Home » Keywords: » PackML

Items Tagged with 'PackML'

ARTICLES

Automation

How 4 OEMs Implemented PackML

Four OEMs share their experiences implementing PackML in machine design and build.

May 15, 2019

OMAC Column

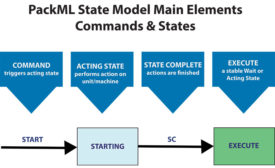

Implementing PackML PackTags

Implementation in an OPC UA server offers potential for end-to-end OEE solutions

December 11, 2018

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing