Software | Taking Machinery to the Next Level

To advance means embracing technological advances at the basic machinery level.

Photo by NicoElNino / iStock via Getty Images Plus

2020 changed everything. As a result, many manufacturers found themselves playing at an entirely new ballpark, and needed to adjust fast. For some, such as those dealing with liquid soap, wipes, and other hygiene consumer packaged goods, it meant increasing production dramatically – working continuously to satisfy market demands. For others it meant to put a certain packaging line to a halt and convert is as quickly as possible into another.

The main challenge for the latter, was the fact that switching packaging lines to deal with different featured ones, meant operational downtime, as the machines stopped for manual reconfiguration or reconfiguration of the packaging production line. One might argue that while this is a big inconvenience and does in fact damage the company’s profits, there’s no real danger. But what about life-saving and critical packaging needs?

Since 2020, the demand for healthcare packaging has grown substantially. These packaging lines became more vital than ever, as fast, reliable and hygienic packaging lines were in high demand.

Packaging Machinery Vulnerabilities

Dealing with unexpected events of 2020 is just one of many scenarios which the packaging professional might encounter and be set out for. Being a field leader often means providing solutions in both likely and unlikely events – and being able to bridge the gap over certain vulnerabilities makes the real difference.

A key vulnerability of the packaging industry is communication. Over decades various aspects of the packaging machinery and process made substantial improvements. Materials became more durable and cost-efficient; processes became smarter and faster; other features increased in abilities — all but communication.

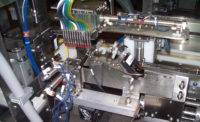

Packaging machinery relies on fast, robust and deterministic communication to enable high-capacity production that is continuously increasing. Yet, key parts of the packaging machinery such as rotating components, free-running movers and shuttles were lacking appropriate communication means due to their dynamic and high-speed motion. The result of which was not being able to monitor the production data, realizing malfunctions only when products reached the end of the production line, and most important of all — gaining control while in motion on all such devices.

The Next Level Packaging

Addressing these needs and achieving next level packaging, require next level communication – and that’s IO-Link Wireless. Having been used across different industries, the wired IO-Link protocol gained reputation and momentum over the years. The next evolutionary step soon followed in the form of its cable-free version: IO-Link Wireless. Being developed within the IO-Link consortium (consisting of such global leaders as Siemens, ifm, Schneider Electric, Zimmer Group, and others), the protocol extension soon proved to be the answer to the packaging industry’s needs.

As an example, independent mover transport systems are a key element in the design of new packaging machines. However, movers are limited as they cannot support real-time communication of actuators and sensors. Cables are not an option due to the range of motion – therefore, a robust, fast, and reliable wireless communication solution is required on each mover. IO-Link Wireless allows products to be processed in an agile and synchronized manner while in constant motion. This eliminates changeover and tooling setup, reducing downtime and enabling high capacity and flexible production lines.

Packaging lines are required to collect a vast amount of meaningful data from numerous sensors in the most cost-effective manner on existing and new machines. An industrial wireless solution enables ongoing data collection from packaging machines from hundreds of sensors within a single machine area. While IO-Link Wireless itself provides the scalability, modularity and reliability, its complementary products also enable retrofitting existing machines into wireless ones. This means that in order to covert a packaging line into a wireless one, there’s no need to buy new machines and equipment, but rather integrate the wireless components into existing machinery in a quick and efficient process. This simplifies machine deployments, relocations and upgrades, in addition to providing analytics and predictive maintenance to all machine components.

The packaging process also includes additional components such as rotary tables, collaborative robots and linear robots, all of which are dynamically moving and rotating. Machines with such components can benefit from IO-Link Wireless for communication by incorporating wireless sensors and I/O directly onto the moving and rotating components, thus reducing maintenance operations and enabling simple future add-on of multiple I/O’s.

Taking packaging machinery to the next level with IO-Link Wireless means that now machine builders and manufacturers can address their top challenges effectively and strategically:

- Support a broad range of package variations (size, weight, shape, material) within a single machine

- Reduce and eliminate changeover and setup time between different package types

- Increase machine capacity by performing actions while in constant motion

- Machine footprint reduction

- Simple to upgrade/adapt for future products

- Predictive maintenance & downtime reduction

- Reduce maintenance cost — less mechanical parts, less wear out, preventive maintenance

- Hygienic design — reduce cables, chains, conveyor belts

Changing the Packaging Industry

Wireless industrial connectivity solutions enable connecting all levels of the plant – top to button, as it connects the lowest level of the factory for the first time in a suitable wireless manner. This leads to the convergence of IT and OT and gives management full view of all aspects of the business. The advantages of IO-Link Wireless have been noted by numerous worldwide leaders such as AB InBev, Schneider Electric, SKF, Cloostermans, and Zimmer Group.

Another major vote of confidence in IO-Link Wireless was recently given by Verizon Ventures. The communication giant, well known for leading the 5G market, realized this potential and took part in the funding of further development of technology and market-share of IO-Link Wireless.

Creating a go-to market and operational plan are not the only ingredients for success. Creating a forward-thinking strategy that creates a paradigm shift in a world of mass customization and dynamic requirements is a critical success factor.

Daniely will be speaking at the “PACK to the Future” stage at the upcoming PACK EXPO, taking part September 27-29, 2021.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!