Home » Keywords: » sensor technology

Items Tagged with 'sensor technology'

ARTICLES

Software | Taking Machinery to the Next Level

To advance means embracing technological advances at the basic machinery level.

October 12, 2021

Leuze Offers Reliable Detection of Multipacks

The DRT25C.R from Leuze detects various film-wrapped bottles and cans fault-free. It uses the conveyor as a reference, and because the detection does not rely on objects, no adjustments are required when changing products.

June 1, 2021

Automation

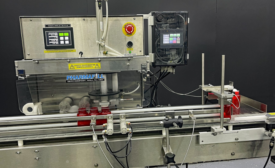

Remote Service Keeps Productivity in Line

Accelerate production line recovery, while reducing lost time and money, with remote monitoring.

October 17, 2019

Automation

Integrating Automation for Packaging Processes

The packaging automation realm needs to embrace change with new technologies.

September 16, 2019

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

-Photo-credit-Emerson_AVENTICS_652_AF2_web.jpg?height=168&t=1632947200&width=275)