31 Million Aluminum Cans Captured Annually with Help of Recycling Grants

(Courtesy of Can Manufacturers Institute)

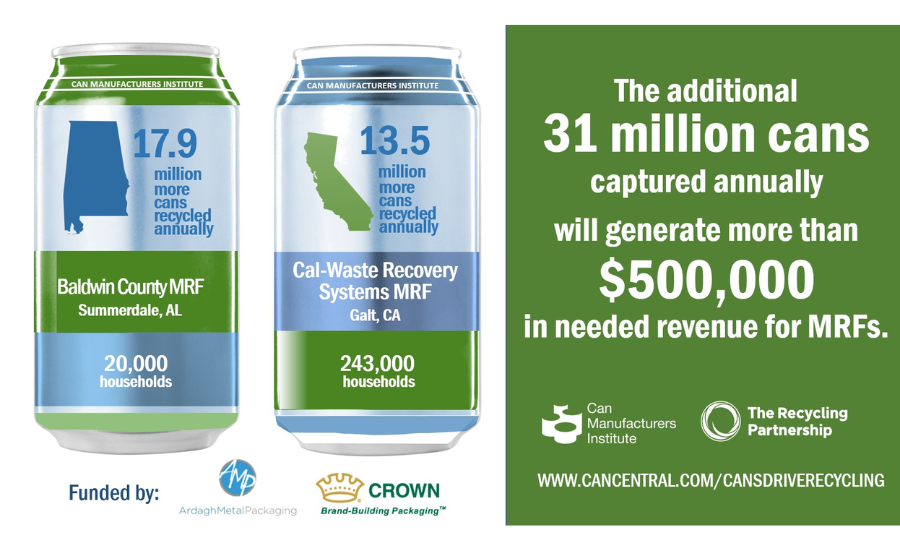

Thanks to grants funded by Ardagh Metal Packaging (AMP) and Crown Holdings (Crown), material recovery facilities (MRFs) in Alabama and California now have equipment that is estimated to capture more than 31 million aluminum beverage cans annually for recycling that otherwise likely would have been missorted or sent to landfill.

These are the seventh and eighth grants that AMP and Crown have financed in Can Manufacturers Institute’s (CMI) MRF can capture program. The Recycling Partnership has administered all eight grants. Collectively, this investment has funded equipment that will capture nearly 150 million aluminum beverage cans annually.

“The best way, in the immediate term, to collect millions of additional cans for recycling is through capturing missorted cans at material recovery facilities,” said John Rost, Senior Vice President of Crown Technology, Global Sustainability & Regulatory Affairs, Crown Holdings. “Crown is pleased to help finance equipment that quickly delivers so much more recycled aluminum. We can then utilize that material to build on our industry’s 71 percent average recycled content in aluminum beverage cans.”

The impact of these millions of cans recycled each year is enormous. According to CMI’s can recycling impact calculator, the more than 30 million aluminum beverage cans recycled each year from the two most recent grants will generate more than $500,000 in revenue, avoiding the CO2 equivalent emissions of driving more than 7.6 million miles. Further, with the nearly 150 million aluminum beverage cans recycled annually from all the grants to-date, the impact represents approximately $2.3 million in revenue and energy savings equivalent to powering more than 6,000 U.S. homes for an entire year.

“Missorted cans are a missed opportunity to drive additional revenue for the U.S. recycling system, strengthen the domestic circular economy, and deliver carbon savings,” said Jens Irion, CEO, AMP-North America. “Ardagh Metal Packaging is proud to do its part to ensure more aluminum beverage cans are properly recycled.”

Here’s more information about the newest grants, announced today:

- Baldwin County, Alabama’s publicly owned MRF serves 20,000 households. The can capture grant helps finance the installation of an eddy current separator at a new MRF built with public ownership. An eddy current uses magnetic forces to separate out non-metallic metal like aluminum beverage cans from other non-metallic materials. This installation prevents missorting by ensuring a best-in-class design for capturing aluminum beverage cans and will result in 516,000 pounds (17.9 million individual cans) of new aluminum captured per year. This MRF is also receiving a grant from The Recycling Partnership for equipment to sort PET and Polypropylene as well as another grant from the Partnership to improve access to recycling collection throughout Baldwin County.

- The Cal-Waste Recovery Systems MRF in Galt, CA serves 243,000 households. The can capture grant embeds AI and new recognition technology into sorting equipment to increase can capture. This upgrade will result in 388,000 pounds (13.5 million individual cans) of new aluminum captured per year. This MRF is also receiving a grant from The Recycling Partnership’s PET Recycling Coalition.

“The Recycling Partnership continues to support communities like Baldwin County, Alabama and Galt, California by mobilizing voluntary investments that modernize facilities and improve residential recycling programs,” said Adam Gendell, Director of Materials Advancement with The Recycling Partnership. “Our can capture grants consistently deliver millions of used aluminum beverage cans and improve recycling for millions of people.”

The can capture grant program is part of CMI’s comprehensive effort to spur the installation of equipment in MRFs to capture missorted aluminum beverage cans. Based on research from 2020, CMI found up to one in four aluminum beverage cans are missorted at a typical MRF. Without the revenue from used beverage cans, most of these facilities would not be able to operate without a change in their business model.

Along with the research and grants, CMI conducted testing in 2022 at several MRFs proving the number of cans being missorted and the return-on-investment (ROI) to capture them, followed by a free ROI calculator for MRFs to use.

Most recently, CMI has financed robots with a revenue share model. In September 2023, AMP and Crown fully financed a two-year lease of an EverestLabs robot in Fresno, California, followed by another EverestLabs robot in May 2024 in Chicago, Illinois.

“The can capture equipment grant and revenue share financing program is a key part of CMI’s effort to reach its ambitious U.S. aluminum beverage can recycling rate targets,” said Scott Breen, Senior Vice President of Sustainability at CMI. “Thanks to funding from Ardagh Metal Packaging and Crown Holdings, now, millions of additional cans will be recycled. These cans are likely to quickly become new cans considering 97 percent of recycled aluminum beverage cans in the United States become new cans and on average aluminum beverage cans go from recycling bin to newly formed can in less than 60 days.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!