Inspection/Detection

From Wine to Tortillas: Inspection, Detection, and Vision Systems Play Crucial Role

From properly counting out pharmaceuticals to guaranteeing the proper bottling of wine — and even ensuring that the wine bottles themselves are up to snuff — inspection, detection and vision systems play a myriad crucial roles in CPG packaging.

Image courtesy of Norwalt

Reporting by Packaging Strategies over the last several months reveals the innumerable applications of inspection/detection/vision equipment.

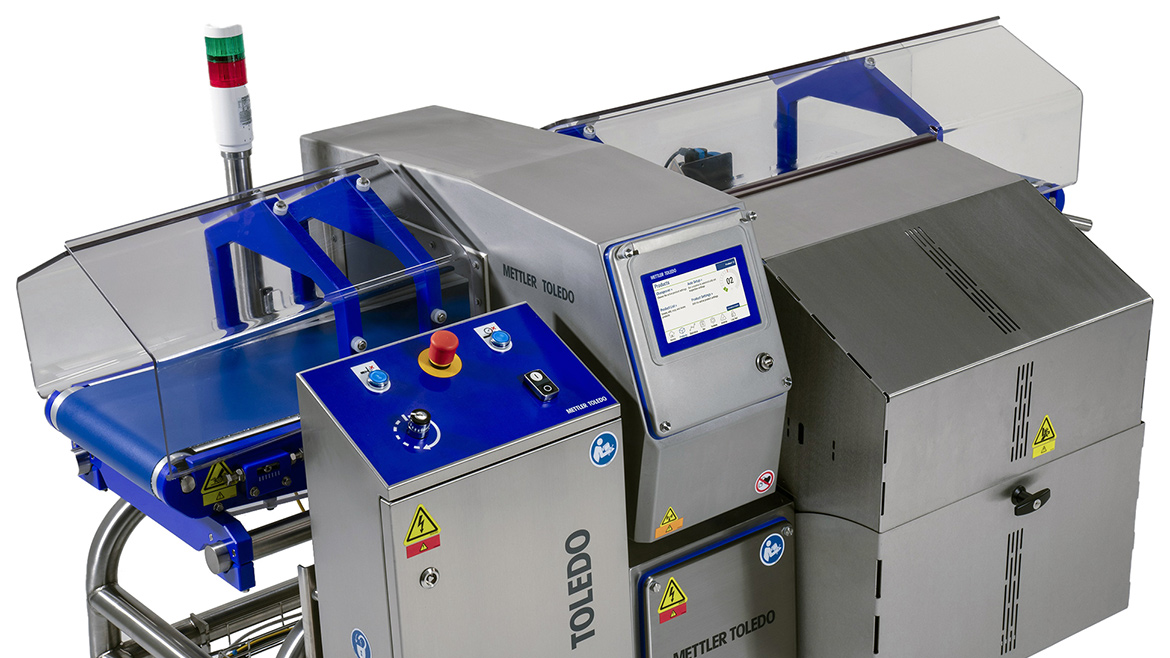

Most recently, Mettler-Toledo showcased several of its product inspection systems at the Interphex trade show in New York City (April 16-18). More specifically, the company showcased pharmaceutical and biotech inspection technology.

One example is Mettler-Toledo’s CV35 “combination system,” which integrates a checkweigher with vision inspection. “This combo solution detects and rejects under- and overweight packages to ensure legal weight requirements are met and reduce product giveaway, while offering a variety of label inspection capabilities including verification that the weight printed on each label matches the weight of each product,” the company notes.

Meanwhile, Antares Vision Group recently introduced a noninvasive, inline pressure measurement system providing reliable, high-speed inspection for beverages in glass and plastic bottles. For the wine sector, the company’s PCS 700-IoT system enables in-line oxygen measurement to evaluate the efficiency of the inertization process after bottle closing.

Ishida has provided a leak detection system for a product that might not immediately come to mind as requiring package inspection: tortillas. However, the inspection equipment plays a critical role. The tortillas are made without preservatives but have a shelf life of six months thanks to their protective carbon dioxide and nitrogen atmospheres — provided that the thermoformed packaging is absolutely airtight.

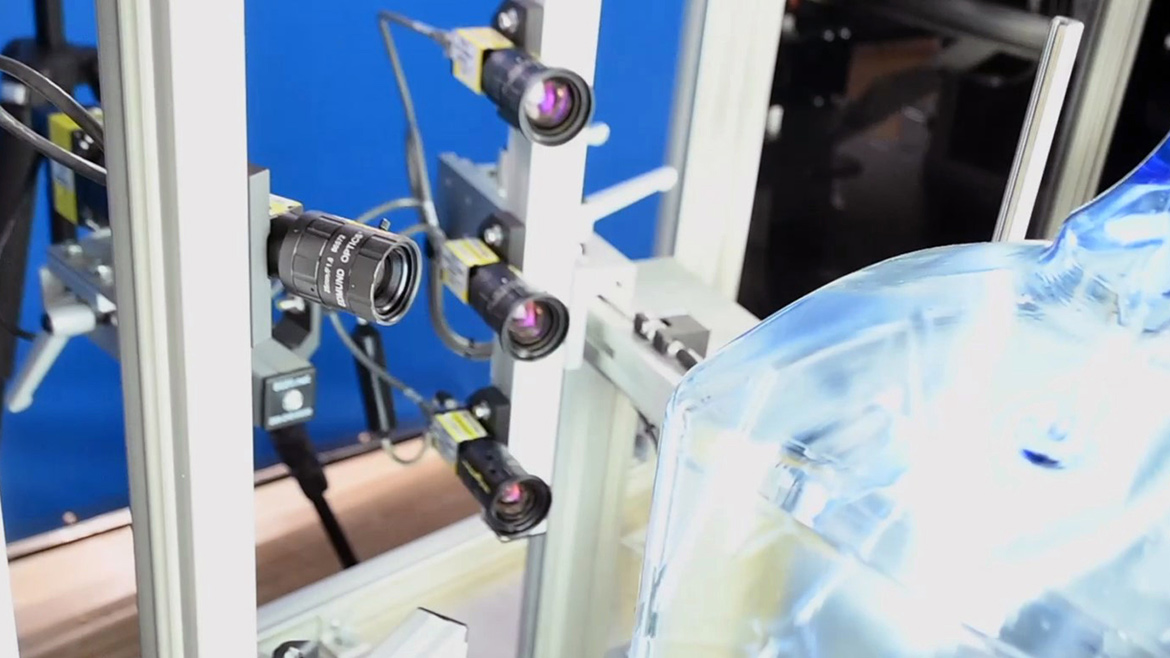

Not to be outdone, Norwalt has engineered one of its most sophisticated bottle vision inspection systems to date. The company’s Vue Inspection System integrates standardized vision components with custom-made elements and deep learning tools. The system is able to monitor gauging defects as miniscule as 10 thousandths of an inch on a translucent surface, a mission accomplished using shape transformation on the sloped areas of bottles.

Learn more about these exciting new developments in inspection, detection and vision.

Mettler-Toledo Showcases Product Inspection Systems at Interphex

The M31R, Mettler-Toledo’s newest metal detector, utilizes sophisticated algorithms to deliver improved detection sensitivity with minimal false rejects. Courtesy of Mettler-Toledo

Mettler-Toledo Product Inspection Group exhibited a wide variety of their world-class pharmaceutical and biotech inspection technology in booth #2361 at Interphex, held at the Javits Center in New York City, April 16-18, 2024.

These x-ray systems, metal detectors, checkweighers and vision systems help customers protect product safety and comply with regulatory requirements while improving process efficiencies.

“Of course, our primary goal is to help product manufacturers and contract packers eliminate any foreign material contamination and minimize the chance of improperly filled or mislabeled packages, but we do so much more to help them succeed,” said Robert S. Conrad, Sales Director – Pharma at Mettler-Toledo. “Our easy-to-use automated systems minimize labor requirements and allow new operators to come up to speed quickly. Electronic connectivity and data management tools like our ProdX software seamlessly transmit and compile digital documentation. And our large network of knowledgeable service technicians further contributes to the best system performance and uptime.”

Antares Vision Group Introduces Inline Pressure Measurement System for Beverages

Antares Vision Group’s PCS700-IOT offers several advantages over the acoustic technologies widely used in the beverage market. For example, detection via laser spectroscopy is significantly more precise, meaning false rejects are substantially diminished. Courtesy of Antares Vision Group

Antares Vision Group, a technological partner in digitalization of products and supply chains for companies and institutions, and leader in traceability and inspection for quality control, has introduced a noninvasive, inline pressure measurement system providing reliable, high-speed inspection for beverages in glass and plastic bottles.

Applicable for all transparent and semi-transparent bottles, the company’s PCS700-IOT utilizes advanced laser spectroscopy technology to precisely determine whether a container headspace has appropriate pressure levels. Among other benefits, the result is accurate, non-destructive leak detection and process optimization.

Through a technique called Tunable Diode Laser Absorption Spectroscopy (TDLAS), the PCS700-IOT analyzes specific molecules in their gaseous state — in particular, their ability to absorb light at certain telltale wavelengths. The laser beam passes through the bottles in the product-free headspace.

Ishida Leak Detection System Provides Crucial Quality Checks for Tortilla Pro

The installation of an Ishida AirScan leak detection system at Sinnack Snacks, Germany’s only large-scale bakery to focus on tortillas, has enabled the company to automate its end-of-line packing process. Courtesy of Ishida

The installation of an Ishida AirScan leak detection system at Sinnack Snacks, Germany’s only large-scale bakery to focus on tortillas, has enabled the company to automate its end-of-line packing process, while ensuring that its quality control procedures are able to keep pace with the increased throughput.

The Ishida solution can inspect as many as 2,500 packs per hour, reliably detecting leaks as small as 0.5mm to ensure the integrity of the protective atmosphere packaging.

Sinnack Snacks produces wheat, multigrain and protein tortillas in diameters of 20, 25 and 30cm, which are sold in packs of 6, 8 and 12. The fresh products are made without preservatives but have a shelf life of six months thanks to their protective carbon dioxide and nitrogen atmospheres – provided that the thermoformed packaging is absolutely airtight.

Norwalt Introduces Innovative Bottle Inspection System

Norwalt has engineered one of its most sophisticated bottle vision inspection systems to date: the Vue Inspection System. Courtesy of Norwalt

Norwalt, a specialist in custom-built automation and line integration machinery for complex manufacturing applications, has engineered one of its most sophisticated bottle vision inspection systems to date. The company’s Vue Inspection System integrates standardized vision components with custom-made elements and deep learning tools.

Norwalt’s new machine has one overarching, pioneering benefit: its ability to monitor gauging defects as miniscule as 10 thousandths of an inch on a translucent surface. It accomplishes this by using shape transformation on the sloped areas of bottles.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!