Home » Keywords: » artificial intelligence

Items Tagged with 'artificial intelligence'

ARTICLES

Robotics

As companies embrace automation, the advancement of robotic solutions in packaging has become a top priority.

Read More

Inspection/Detection

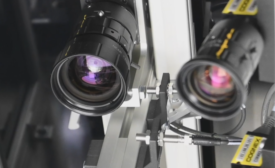

From Wine to Tortillas: Inspection, Detection, and Vision Systems Play Crucial Role

From properly counting out pharmaceuticals to guaranteeing the proper bottling of wine — and even ensuring that the wine bottles themselves are up to snuff — inspection, detection and vision systems play a myriad crucial roles in CPG packaging.

May 28, 2024

Technology is Revolutionizing Cartoning and Case Packing

Augmented Reality and robots with vision are among innovations taking efficiency to the next level.

February 2, 2023

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing