Home » Keywords: » printers

Items Tagged with 'printers'

ARTICLES

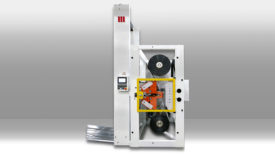

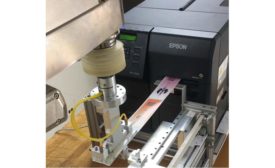

Machinery

It’s all about Tension Control

If there was ever a time to employ waste-reducing technologies, it is now, and precise tension control and automatic roll changing are technologies that go hand in hand.

July 13, 2022

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing