Home » Keywords: » machinery trends

Items Tagged with 'machinery trends'

ARTICLES

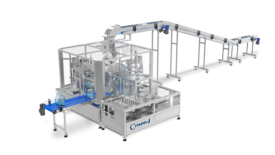

PACK EXPO Preview

New Machine Advances Debuting at PACK EXPO International 2022

September 6, 2022

Machinery

Retrofit Package Sealing Systems for Improved Efficiency, Quality

When the seal on a food package is imperfect, a couple of things can happen. Neither is good for your business. Is now a good time to think about upgrading outdated equipment?

February 8, 2022

Automation

Remote Service Keeps Productivity in Line

Accelerate production line recovery, while reducing lost time and money, with remote monitoring.

October 17, 2019

Automation

7 Tips for Choosing Cleanable Packaging Equipment

Machines incorporating sanitary design can improve the bottom line by lowering the risk of product recall and improving productivity.

October 15, 2019

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing