Home » Keywords: » xray machinery

Items Tagged with 'xray machinery'

ARTICLES

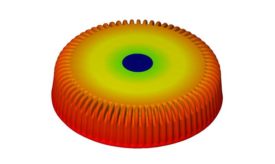

Package Detectability

Technology Advances X-ray and Metal Detector Inspection Capabilities

Metal detectors and X-ray machines both have a place on the production line, and different packaging types and products can affect their performance.

March 30, 2021

Machinery

Staying Competitive in Challenging Times

Manufacturers look to invest in X-ray inspection equipment to set the stage for brand protection and future growth.

July 11, 2020

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing