Home » Keywords: » flexible plastic packaging

Items Tagged with 'flexible plastic packaging'

ARTICLES

Materials

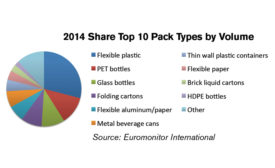

The Importance of Flexible Packaging

Three key insights cement why flexible packaging is, and will remain, a premium packaging solution.

May 11, 2020

PS News Special Report: Pack Expo Review

Flexible, Sustainability on Show at Pack Expo

October 30, 2015

PMMI announces findings of Retail Ready Packaging study

Economic growth and urbanization have lead to an increase in retail ready packaging markets around the world

May 29, 2014

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing