Home » Keywords: » packaging production

Items Tagged with 'packaging production'

ARTICLES

Spotlight Feature

Experts share tips and ideas on taking your packaging line to the next level.

Read More

Automation

7 Tips for Choosing Cleanable Packaging Equipment

Machines incorporating sanitary design can improve the bottom line by lowering the risk of product recall and improving productivity.

October 15, 2019

PACK EXPO LAS VEGAS 2017

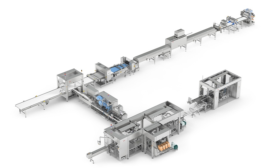

Bosch to showcase production and packaging system for granola bars

August 3, 2017

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing