Unitizing/ Palletizing

Machinery: Palletizing

Finding the Best Solutions for Palletizing & Depalletizing

Knowing your options and selection considerations will help you to make the right decision for long-term productivity gains.

December 12, 2019

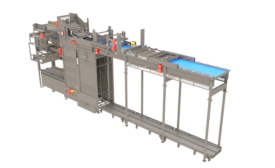

Machinery

Setting Up Equipment for Low-Temperature Operations

How Wulftec beat the cold with pneumatic system enhancements.

September 12, 2019