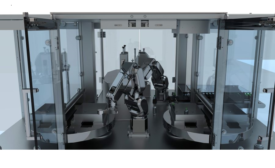

Inspection/Detection/Vision

Spotlight Feature- 2

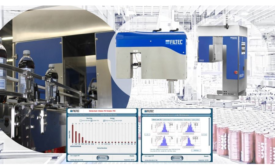

Automated Inspection Protects Brand Quality for Syrup Manufacturer

September 10, 2020

Materials

Tethered Caps & Lids Find a Home

The EU recently introduced a directive on marine plastic litter, and tethered caps and closures play an important role.

July 13, 2020

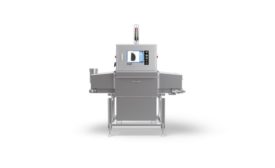

Machinery

Staying Competitive in Challenging Times

Manufacturers look to invest in X-ray inspection equipment to set the stage for brand protection and future growth.

July 11, 2020