Conveyors

Conveyors

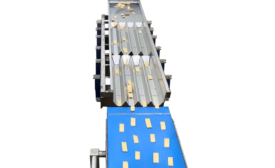

Hygienic Improvements with Conveyors Allow Streamlined Packaging Process

Embracing efficiency

December 14, 2023

Machinery

Selecting the Right Sanitary Conveyor Platform for Food Packaging Application

Conveyors are a prime target for contamination, but understanding the nuance of how equipment works with specific applications ensures upgrade success.

March 8, 2022

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing