Robotics

Cover Story

Robotics and the smart factory

Smart machines and industry 4.0 accelerate productivity

September 18, 2017

PACK EXPO Las Vegas 2017

Omega Design and MACTEC team up on unit dose packaging

August 30, 2017

PACK EXPO Las Vegas 2017

Redesigned mini robotic pallet cell to show off at PACK EXPO

August 22, 2017

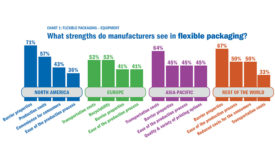

Machinery Technology: Automation

To automate or not: 3 points of concern for biscuit manufacturers

August 16, 2017

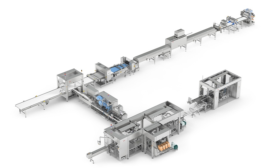

PACK EXPO LAS VEGAS 2017

Bosch to showcase production and packaging system for granola bars

August 3, 2017