Machinery

WS Packaging group introduces new lineup of label application equipment

Business unit for application equipment renamed WSAutomation

August 27, 2013

Machinery Technology: Coding & marking

Printing solutions deliver benefits to food and beverage packagers

Innovations and advancements leave their mark.

August 14, 2013

PMMI Corner

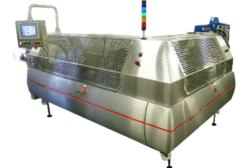

X-Ray vision

In a climate with increasing concerns regarding food quality, leading manufacturers use the latest in X-ray inspection technology to protect products, consumers and ultimately, their brands.

August 2, 2013

Ryson introduces 10” high capacity mass flow spiral conveyor

Unit adds diversity to line of mass flow vertical conveyors

July 31, 2013

Tapeswitch offers programmable safety laser scanner

Compact, lightweight, easy to use scanner offers wide area coverage.

July 26, 2013

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing