Machinery

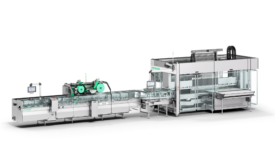

Form/Fill/Seal Equipment Manufacturers Responding to New Demands in Sustainability

New demands include films that allow for more sustainable packaging but also offer the same durability and performance as prior options

June 5, 2023

Machinery

Catching Errors at High Speed

ISRA VISON, Bosch Rexroth and Teledyne TapTone are among companies offering much-needed inspection and detection technology to the packaging industry

April 24, 2023

Materials

Ink Technologies Growing Increasingly Sophisticated

Companies are seeking innovation and versatility to meet a broad range of goals and demands, from adhering to track-and-trace regulations to sourcing sustainable inks that meet stringent food and pharmaceutical packaging requirements.

April 6, 2023

Editor’s Note

Innovation, Rising Global Demand Keep Packaging Industry Optimistic

Just as baseball fans are excited about this year’s pioneering schedule, the packaging machinery industry has a lot to look forward to in 2023

April 3, 2023

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing