Home » inspection and detection machinery

Articles Tagged with ''inspection and detection machinery''

Machinery

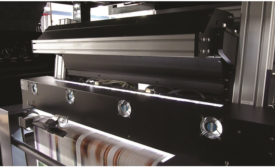

Catching Errors at High Speed

ISRA VISON, Bosch Rexroth and Teledyne TapTone are among companies offering much-needed inspection and detection technology to the packaging industry

April 24, 2023

Package Detectability

Technology Advances X-ray and Metal Detector Inspection Capabilities

Metal detectors and X-ray machines both have a place on the production line, and different packaging types and products can affect their performance.

March 30, 2021

Machinery: Case Study

Inspection Lines Do the Trick for Frozen Desserts

J&J Snack Foods chose X-ray systems that offer impressive features at an affordable price.

July 15, 2019

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing