Home » printing technology

Articles Tagged with ''printing technology''

Podcast | Ink & Labeling Sustainability

From the Packaging Perspectives podcast series

April 24, 2023

Pioneers in Sustainable Packaging are Winning Recognition

New technologies and conscientious operational practices are among drivers of success in moving toward sustainability.

February 10, 2023

SÜDPACK Showcases “Flow Pack Purepp” for Ground-Meat Products at EMPACK

September 16, 2022

Printing

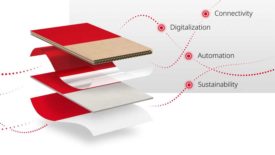

The Perfect Partnership: Profitability and Sustainability Go Hand-in-Hand for Package Printing

Far from increasing operating costs, sustainability is often the key to saving money and increasing profitability.

August 3, 2022

Printing

Tips for Better Flexible Film Coding

Flexible film is today’s fastest-growing category of packaging, finding uses in a wide range of products. As a digital technology designed for flexible film, Thermal Transfer Overprinting offers many advantages over alternatives.

October 11, 2021

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing