Home » case packing technology

Articles Tagged with ''case packing technology''

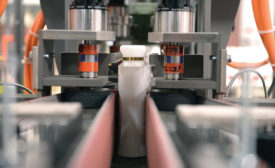

Leuze Offers Reliable Detection of Multipacks

The DRT25C.R from Leuze detects various film-wrapped bottles and cans fault-free. It uses the conveyor as a reference, and because the detection does not rely on objects, no adjustments are required when changing products.

June 1, 2021

Machinery

The Skills Gap: Is Packaging Half-Full or Half-Empty?

As suppliers design end-of-line equipment to meet today’s packaging needs, the industry holds great promise to close the skills gap.

June 10, 2019

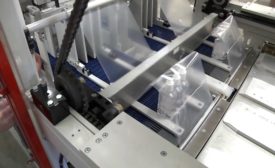

Machinery Technology: Case Packing

How to optimize the end of a flexible packaging line

Bag Sealed, Case Closed

March 1, 2018

Machinery Technology: Case Packing

Winning the case with automation equipment

Moving to semi- or fully automated equipment could increase production, save cost on equipment and ensure quick changeover.

October 5, 2017

Keep the info flowing with our eNewsletters!

Get the latest industry updates tailored your way.

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing