New product from Maplesoft Improves Web Handling Equipment

Source: Maplesoft

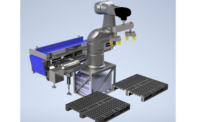

Maplesoft announced a new addition to the MapleSim family of products that allows design engineers to model roll-to-roll product lines and include web handling in machine simulations. The new MapleSim Web Handling Library is an add-on to MapleSim, a system-level modeling and simulation tool that enables machine designers to reduce development time, lower costs, and diagnose performance issues. The MapleSim Web Handling Library expands the modeling scope of MapleSim by adding rollers, drum brakes and other components that can faithfully simulate a machine’s handling of paper, plastic film, textiles, or foil. In addition to this new library, Maplesoft has released updates to the entire MapleSim family, which provide an enhanced user experience through expanded modeling libraries, new productivity features, and an increase in connector choices. In particular, control engineers can now connect MapleSim’s digital models to even more automation tools using MapleSim Insight to support optimal controller development using virtual commissioning.

Machine builders use system-level models at the early stages of automation design to predict the operating performance and to optimize machine responses. MapleSim is used to create a high-fidelity model of the machine that can be run through testing and simulation scenarios before a physical prototype is built. For production lines that include continuous rolls of paper, textiles, plastic films or foils, known as web, trying out different roller locations and tensioning options virtually means the most effective choices can be determined at an early stage. Design revisions that would be costly to make after prototyping can be applied to the digital model for a fraction of the time and effort. Using MapleSim and the MapleSim Web Handling Library, the engineer can proactively test physical changes, such as adding extra nip rollers or dancers and determine the impact of adjustments to the controller code. Users can then visualize the torque, tension, and web motion in 3-D. This information can be used to limit the fluctuations in tension that result in poor quality for downstream processes or even tear or stretch the web.

“Automation companies today are constantly reviewing operations to determine if a machine can run at a higher speed, perform with less vibration, or operate more efficiently if a different motor, actuator, or other component is used,” says Chris Harduwar, vice president of business development at Maplesoft. “By starting with a MapleSim model and adding production data, customers get a faithful representation that can respond to different parameters and layouts just as the physical line would. When dealing with paper, foils, and films the MapleSim Web Handling Library can be used to find web speed improvements and solutions to control code problems before having to change hardware, saving time and money.”

In addition to the software, Maplesoft also offers full-service solutions for diagnosing, fixing, and optimizing machine performance, without anyone in the organization needing to become a modeling expert. Maplesoft will work with customers to create a digital model that can yield powerful, cost-saving results, and then run this model in MapleSim Insight, which provides simulation-based 3-D visualization and debugging capabilities and connects directly to common automation platforms.

As part of this release, the new version of MapleSim Insight now understands the EtherNet/IP industrial protocol and provides the means for almost any PLC programming environment to use a MapleSim model in a virtual commissioning workflow. As a result, tools like CODESYS join the list of connecting programs, alongside the previously supported software from B&R, Beckhoff and Rockwell Automation.

Other improvements to MapleSim and its add-on libraries, toolboxes, and connector add-ons include features that save time when creating and analyzing models and add fidelity for specialized domains such as tire behavior on different terrains and winches with ropes and cables.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!