High Payload Product Handling Solution Debuts

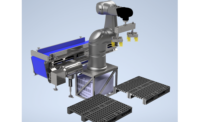

JLS Automation is helping meat and poultry producers work more efficiently and safely with a new sanitary, high-load bulk product handling solution.

The new flexible robotic solution effortlessly loads large cuts of protein, such as naked pork belly slabs, into processing equipment. In addition, it can also stack the same large cuts on a pallet after the primary packaging process, such as vacuum packaging or thermoforming. The JLS bulk product handling system features a high payload, ensuring quick cycle times and a long-reach arm ensures care in handling food products.

According to JLS, the six-axis Stäubli robot utilized in this new sanitary solution features a maximum payload of 220 pounds with a reach that extends up to 8-1/2 feet. The robotic bulk product handling arm can be mounted in a variety of orientations, including inverted.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!