Decaser Automates Reship Case Hand Dumping

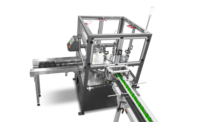

Packagers who receive their glass or plastic containers in necks down reshipper cases can automate their hand dumping operation, reduce costs, increase line speeds and ensure a consistent bottle supply to their filler with A-B-C’s (abcpackaging.com) Model 49 decaser. The Model 49 accepts cases from the conveyor either back-to-back or spaced, unloads and single files containers, and uprights the empty cases for transfer to case packing.

Containers glide from the case to the impact-absorbing transfer belt and bottle contact is minimized with A-B-C’s single filing module. These features work to maintain bottle stability and protect the integrity of lightweight glass containers. By replacing the hand dumping operation, the decaser eliminates the related risk of employee injury from repeated lifting and emptying of heavy cases.

The decaser has features to accommodate case size variations, including a soft roller system that utilizes an automatic tensioner to ensure smooth case transit throughout decasing. The 180-degree case turnover securely holds the cases as they are oriented before discharge. The Model 49 decases plastic or glass containers from RSC, HSC and RSC tablock cases at speeds to 60 cpm, and offers quick and easy changeover.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!