AVT to demonstrate advanced in-line solutions at Metpack 2017

AVT (avt-inc.com), a leader in print inspection, print process control and quality assurance solutions, will provide live demonstrations of Titan, an in-line 100% inspection solution for metal decorating applications and Mercury, a digital ink control system, at METPACK, May 2-6, 2017, in Essen, Germany. Located at Booth 1E27, AVT also will showcase a set of workflow & automation solutions.

AVT’s inspection solutions reduce print waste and increase productivity by shortening make ready time and pinpointing emerging defects in their early stages, before they devolve. The assurance provided by so trustworthy an inspection system results in both faster run speeds and improved quality of printed goods, with significantly reduced needs for over-prints and re-prints.

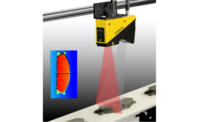

AVT's Titan is a comprehensive quality assurance and process control solution providing 100% inspection and traceability of every printed metal sheet. Based on the company’s advanced quality control algorithms, the state-of-the-art solution is tailored to the specific challenges of metal printing and decoration. Titan detects the full spectrum of typical print defects including color variations, mis-registration (including varnish mis-registration), misprints, spots, text, streaks, scratches, splashes, scumming, edges, bends and more.

Titan’s additional quality control aspects include PDF comparison and color variation tracking, as well as PrintFlow, a generated report enabling easy defect tracing for subsequent analysis. Connected to the customer's workflow, Titan can send signals to ejectors and/or feeders, helping to reduce costly material waste.

AVT’s workflow solutions complement its inspection systems through a full range of capabilities. Offline Setup enables customers to perform setup for Titan, based on the PDF of the job, offline; this is essential when run lengths are becoming shorter and shorter, and customers must handle changeovers as quick as possible.

Furthermore, AVT's PrintFlow Manager enables customers to monitor, analyze and control their production quality; identifying problems in the production process allows customers to save valuable production time and waste.

AVT also will demonstrate Mercury, an ink-keys control system that precisely sets inking using a patented, digital servomotor on any new or existing litho decorating line. Employing a highly intuitive, touch screen control station for easy operation, the system applies corrections to the ink keys of digital pre-set files based on previously run jobs or digital job files, resulting in gradual improvements of pre-set accuracy. As such, Mercury becomes incrementally more efficient – and therefore, more valuable – over time, reducing pre-setting, startup time and materials waste up to 50%.

“For canmakers and other metal printers and decorators, the opportunity to increase production speed while also improving accuracy is a win-win, allowing them to recoup their investments in a relatively short timeframe,” says Amir Sheinman, vice president of marketing for AVT. “Titan provides unsurpassed abilities for correcting defects before they become widespread, and for ensuring color consistency to meet brand specifications.”

At METPACK, AVT also will demonstrate, for the first-time, Mercury's programmable 'ramping' control for ink-feed and ducting rollers, ideal for improved control of especially challenging layouts.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!