Lock N' Pop introduces transportable applicator unit

Lock N’ Pop™ (locknpop.com), a premier load containment solution provider from Muller LCS and part of SIG, introduces a new transportable applicator unit for its water-based cohesive that forms a chemical bond with packaging surfaces and holds firm until it’s time to un-stack the pallets. Providing greater flexibility, the Lock N’ Pop transportable applicator unit allows users the ability to configure cohesive where needed.

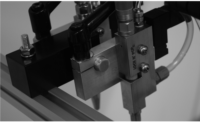

Traditionally, applicators are mounted to a conveyer or machine. However some applications create challenges for incorporating applicators. For example, there may be too many motors or gear boxes on the machine that are in the way or a conveyor is too high above ground to reach. With a durable aluminum frame, slim design and telescoping parts, the transportable applicator unit can be customized to various demands. It can also be ordered with just the right number of applicator guns. For smaller sized packaging applications, two guns are used versus regular-sized packages, which require four.

“The Lock N’ Pop cohesive has long been trusted as a premier load containment solution for those looking to reduce waste while keeping pallets secure in transit,” says Rosanna Cavanaugh, business manager, Lock N’ Pop and Lachenmeier NA. “The transportable applicator unit allows manufacturers to reap the benefits of greater efficiency where otherwise not easily accessible.”

For seasonal manufacturing facilities or plants with multiple lines in close proximity, the transportable applicator unit increases productivity. Rather than buying or retrofitting multiple machines with applicators, the unit can alternate machines or lines.

“Our solutions are all intended to reduce waste and improve overall load containment efficiencies,” says Cavanaugh. “The transportable applicator allows for greater versatility ultimately, helping customers’ bottom line.”

Lock N’ Pop cohesive can be applied with or without Lock N’ Pop equipment- which is compact, inexpensive and virtually maintenance-free. Unlike solvent or latex based materials that may be hazardous or difficult to clean and maintain, Lock N’ Pop solutions are completely water-soluble and require minimal maintenance on application equipment. Formulated with FDA approved ingredients, the cohesive can be applied to ambient as well as refrigerated or frozen goods.

Lock N’ Pop’s water-based cohesive is stronger than stretch wrap alone and is cold applied making it safer than hot melt. It does not leave a sticky residue or harm packaging surfaces when unstacking/popping product apart. Lock N’ Pop further allows for heavy reductions in traditional packaging – stretch film, slip sheets, dunnage bags, corner boards, and more can be virtually eliminated while maintaining proper load security.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!