Liquid filling machines for wine & spirits

Distilleries: how to use liquid filling machines for wine & spirits

Artisanal distillers, craft distillers, and micro distillers are some of the facilities that require liquid filling machines intended to handle the various types of wines and spirits they are likely to produce and bottle. Machinery needs to be able to scale based on the changing production needs. Modern liquid fillers can accommodate for these needs, allowing for complete adaptability to changing environments. Wine and spirit consumers often trust specific companies because of the consistent quality of their products, and liquid filling machines contribute to this consistency in several ways.

There are a couple of types of overflow liquid filling machines that are ideal for filling wine and spirit bottles, based on the viscosity and the type of packaging requirements.

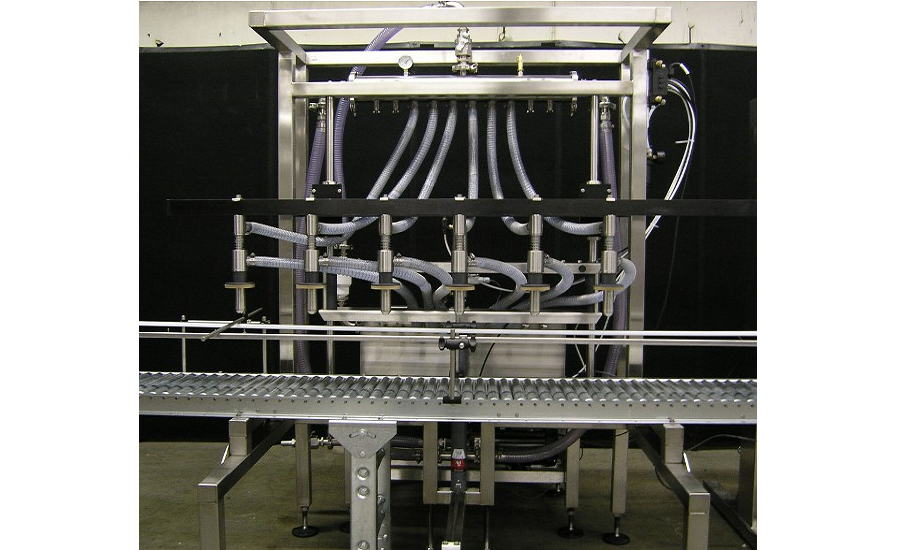

Sanitary Overflow Fillers

One type of liquid filling machine that is commonly used for wine and spirits is the sanitary overflow filler. They are designed with quick breakdown fittings, pumps and valves to use when needed. They can effectively keep bacteria out of wine and spirit packaging throughout the filling process, preventing contamination that can spoil these products prior to consumption. They can also provide a consistent fill level for products that need it.

The easy breakdown of parts allows for simple cleaning, which helps avoid the buildup of bacteria and mold on parts that could potentially leak into products during filling. Like other overflow machines, sanitary overflow fillers are designed to handle low-viscosity to water-thin products, which include most spirits and wines. They are also ideal for applications with transparent bottles that allow for total visibility of the fill level.

Tabletop Overflow Fillers

Some applications don't have the space to handle full-size liquid filling machines, requiring the use of portable or tabletop machinery. If a facility needs overflow equipment that can meet tight space requirements and frequently changing equipment configurations, tabletop overflow liquid fillers are ideal. Like other overflow machines, these tabletop models can fill most low-viscosity to water-thin liquids, while allowing facility managers to place them nearly anywhere in the production line.

The difference between tabletop overflow fillers and other formats is the ability to perform changeover between parts within minutes to reduce downtime when reworking machine configurations. Typical tabletop overflow fillers also provide easy general operation, simply requiring the user to manually place bottles beneath the fill heads using an adjustable railing before successfully filling bottles with the flip of a couple of switches.

Other Types of Liquid Packaging Equipment

While high-quality liquid fillers are vital to the actual filling step of the liquid packaging process, there are many other machines that distilleries should consider when packaging wines and spirits. These machines can include conveyors, spindle or chuck cappers, bottle cleaners (including air rinsers), case packers, palletizers and labelers.

Integrating a sanitary or tabletop overflow filler along with all of this machinery can help ensure that your wines and spirits experience consistently reliable filling, with consistent and accurate fill levels that prevent product wastage and contamination. Facilities will be able to benefit from maximized productivity and efficiency, meeting business goals and consumer demand for wine and spirit products.

A complete system of reliable overflow fillers and other liquid packaging machines will give your facility what it needs to give you the best results when producing wine and spirits.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!