Craft beer trends

Talking craft drinks – Just can it

Following his appointment in 2014 as Tonejet’s Worldwide Sales Manager, Marvin Foreman has been busy supporting the growth of a company on the verge of disrupting the craft beverage market.

“Craft beer is a rapidly growing market and an exciting one to be in. The increased variety of craft drinks being launched shows no sign of slowing, from soft drinks and energy drinks through to ready-to-drink spirit based cocktails and more. - Craft drinks are fast becoming a significant and growing percentage of the overall worldwide beverage market.

With growth, of course, comes competition and larger breweries and drinks companies have taken a keen interest in this market. Some have already diversified their own offerings to capitalize on this trend, and all are looking for creative ways to increase brand/product recognition and most importantly, appeal to the consumer.

Small batch beers have been canned in the USA for some 20 years, and this is undoubtedly on the increase in the UK too. But it isn’t without its barriers. Minimum order levels typically in excess of 150,000, continue to throttle a brewer’s ability to cost effectively grow their business by moving from bottles to cans. Long lead times of 1-2 months and purchasing of excess cans, has also meant that until now, canning craft beverages hasn’t been an option for small to medium-sized breweries. New digital can printing technology is addressing these issues, opening-up a whole new world of opportunity.... and not just for smaller breweries.

In fact, with limited edition flavorings or one-off special brews, digital can printing meets today's beverage demands head-on. From a cost perspective alone, digital can printing is roughly 15 times cheaper than the label printing of cans often used as a short term solution to move from bottles to cans. Cans are a better solution for preserving the beverage from light degradation, as well as storage and transportation.

With the inherent nature of digital print and minimum orders of almost one, brewers are now provided with virtually limitless personalization opportunities. Not only that, but as the technology is capable of printing several batches a day, product time-to-market is decreased too, enabling brewers to respond quickly to seasonal trends or produce and can special brews for events or social media campaign, opening-up new business opportunities.

The ability to digitally print directly onto cans, also opens-up huge opportunities for larger brands/breweries too. They can now cost effectively package their beverages in smaller volumes, with the printing flexibility to version or change the messaging on their cans as required.

By example, a recent Tonejet customer in North America is setting up a contract can printing company, buying in blank cans and printing small run orders for local craft brewers. With no order constraints, even before the system is installed, its order book was full for several months. They are already expecting to invest in a second system to meet demands!”

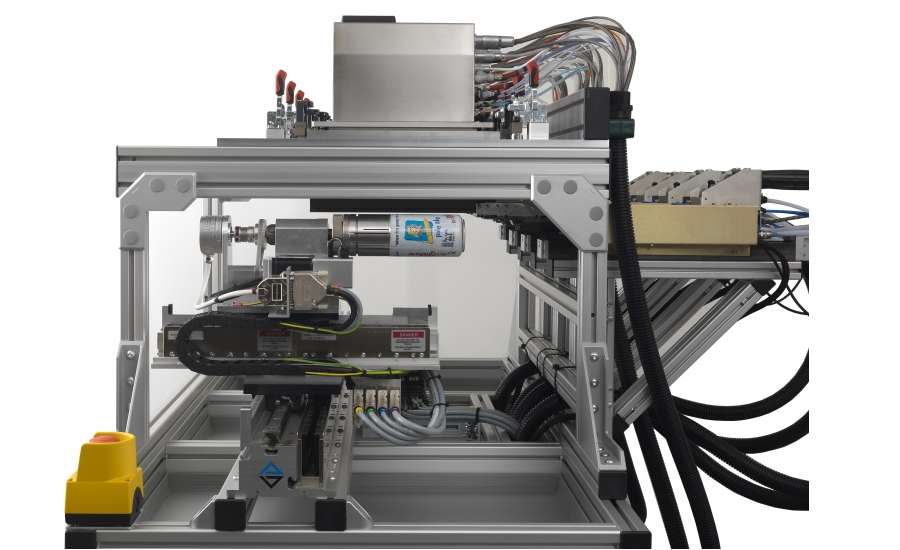

Tonejet, the leading manufacturer of advanced electro-static drop-on-demand digital print engines, called upon Marvin Foreman to help utilize its unique and groundbreaking digital print technology. Foreman is responsible for Tonejet’s worldwide go-to-market sales strategy. Part of this strategy includes educating the industry as to the business building and profit generating benefits of its technology. Foreman will continue to drive sales of Tonejet’s 2-Piece Can & Tube Digital Decorator, while further developing the company’s worldwide sales and service network.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!