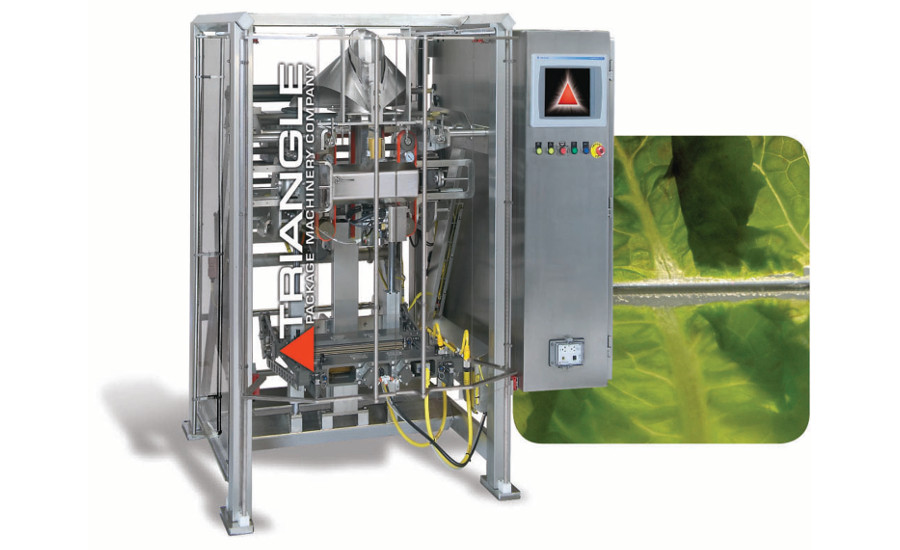

Triangle’s X-Series VFFS Baggers with Ultrasonic technology improve production and OEE; available with Ultrasonic cross seal and back seal

Triangle’s X-Series VFFS bagger with Ultrasonic technology helps food packagers eliminate or significantly reduce leakers, thanks to its ability to seal through food particles and create an airtight seal.

Ultrasonic welding is a cold-sealing technology that allows the bagger’s sealing jaws to seal right through product and push it completely out of the sealing area, resulting in less headspace and improved material savings. Additional benefits include improved product, energy and labor savings, as well as less downtime and improved OEE. Customers rave about the bagger’s ability to improve package quality, save labor, and reduce film and product waste.

With the X-Series VFFS baggers, customers can run Ultrasonic welding or traditional heat sealing on the same machine, thanks to a quick and simple changeover of cross seal jaws. A rotary Ultrasonic backseal is also an option, providing a complete Ultrasonically-sealed package.

>> Click here to learn more about Ultrasonic sealing for your packaging application.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!