Web Exclusive

Challenges and forecasts in the packaging barrier films market

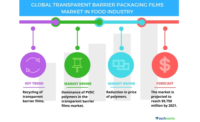

As plastics have become more and more common in packaging, concerns have arisen about their ability to compromise the quality and safety of products. Therefore, there has been a marked increase in demand for packaging materials that give even greater protection to their contents, particularly in the food and beverage sector.

A variety of barrier technologies have been commercialized that preserve, protect, and optimize product shelf life, reduce the need for preservatives, provide transparency and gloss, and serve as a printing substrate. Without such barrier packaging, perishable goods such as food, beverages and pharmaceuticals would be susceptible to a wide range of deterioration processes. Therefore this type of technology has begun to replace more traditional pack types. In this new bulletin, Smithers Pira (smitherspira.com) examines the various challenges and forecasts in the high barrier packaging films industry.

Replacement of rigid pack formats

Consumer and technology trends have contributed to a gradual decline of rigid pack formats in the face of flexible packaging and barrier films during the last decade or so. Busier consumer lifestyles and the consequent demand for convenience products, together with the popularity of microwave cooking have, for example, contributed to the growing use of microwaveable retort ready meals packed in trays or stand-up pouches.

The market for stand-up pouches has grown, due in part to their replacement of plastic and glass bottles and cans, but also because SUPs reduce packaging costs and are more convenient for consumers. Stand-up pouches are lighter weight and have lower material use compared with rigid containers. The heat-resistant retort stand-up pouch is made of laminated plastic films, or foil if microwaving is not required. It can be filled, heat-sealed and sterilized by pressure cooking in a retort (autoclave). As a result, the retort pouch contains heat-treated, cooked food which is safe from micro-organisms and has an ambient shelf-life similar to tinned food. In addition, due to their thinner dimensions, it takes less time to cook food in a flexible pouch than in other forms of rigid packaging such as cans and jars. Foods currently using retort stand-up pouches include ready meals, soups, rice, vegetables and sauces. However despite these inherent benefits, there have been some obstacles on the way to widespread adoption of this technology.

What are the main challenges to barrier packaging?

Barrier packaging is restricted by factors such as susceptibility to degradation, recycling problems and cost. EVOH, for example, is water sensitive because absorption of atmospheric moisture reduces its barrier properties towards oxygen and carbon dioxide.

Mechanical recycling also becomes a problem with multilayer structures containing more than one type of plastic, as they cannot easily be recycled. While multilayer structures are difficult, or even impossible, to recycle mechanically they can be recycled to energy or fuels by incineration, anaerobic pyrolysis or plasma pyrolysis.

Sustainable packaging

There is mounting public pressure on brand owners and retailers to reduce the environmental impact of packaging. Food and beverage manufacturers are also responding to consumers' environmental concerns by reducing the amount of polymer to lower the pack weight but without impacting pack performance. Light-weighting is also driven by a need to reduce packaging costs following sharp increases in polymer prices.

Some companies are taking the need for sustainability one step further by creating biodegradable and renewable cellulose-based barrier films. Innovia Films and Sappi Fine Paper Europe, for example, have combined their individual compostable substrates, Innovia's 'NatureFlex' and Sappi's 'Algro Nature', to provide a packaging solution that offers the potential for either industrial or home composting or anaerobic digestion. Both NatureFlex and Algro Nature are manufactured from wood sourced from managed forests. According to the companies, these natural materials provide the essential barrier requirements of coffee, snack bars and single-serve drink packs.

Barrier film producers often state that barrier films will play a vital role in more sustainable packaging. Many argue that they are more environment-friendly because they help packagers use lighter plastics to replace much heavier materials such as glass, metal and rigid plastics. Flexible plastic packaging requires less energy to transport products than does metal and glass.

Retail trends

High barrier packaging film demand is benefiting from the growing market share of the large retail chains. These chains have expanded the market for packaged food with their focus on cost reduction and shelf-life extension. Retail chains have dominated retail food and drink markets in advanced countries for many years. Food and drink retailing in the developing countries of Central & Eastern Europe, Asia and South America, has traditionally been dominated by small, local and independent artisan stores, largely offering unpacked food. Domestic supermarkets/hypermarkets are spreading in many of the major cities in developing countries and are now taking a growing share of food and drink consumption. International retail chains are also expanding their presence in developing markets, which will further expand barrier packaging demand in these countries, bringing more consumers into contact with Western shopping patterns.

Supermarkets/hypermarkets are becoming especially favored by consumers due to their wide product ranges and diverse choice of premium brands, usually unavailable in the other types of outlets. There has also been growth in the number of discount stores and private label products which enable those on lower incomes to purchase packaged food and drinks at more affordable prices.

To find out more about high barrier packaging films, Smithers Pira’s new report, The Future of High Barrier Packaging Films to 2019, is available to purchase now.

Research compiled by Smithers Pira.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!