Menges roller expands, offers cylindrical finishing & chrome plating for all rollers

Menges Roller Company (www.mengesroller.com) is pleased to announce the expansion of its service offerings. The Menges Team will now provide Cylindrical Refinishing services, as well as Chrome Plating, for all types of rollers – including those used in laminating, extrusion, vacuum coating, plastic packaging, and the various converting processes.

Most of the time, chromed rollers tend to be of the expensive “thermal roll” variety. This includes hot ‘heat-transfer rolls,’ used to optimize adhesion properties in glues and between layers in laminates, and ‘chill rolls,’ often used to cool recently-extruded plastics.

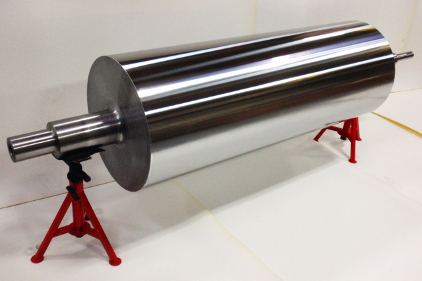

Thermal Rollers are expensive rollers, and plant managers are happy to have them re-chromed for a fraction of the cost of a new roller. Menges Roller will now grind off that old chrome and apply new chrome plating to the roller, delivering a like-new finish.

For converters, a high-gloss finish on chromed rolls is imperative. Especially in those situations where rollers are in contact with hot plastics, if the chrome is dull, the plastic finish will appear dull and “un-glossy”.

Few roller companies offer precision cylindrical grinding & re-chroming. However, Menges Roller Company has invested heavily in computer controlled outside diameter finishing machines which are capable of achieving diameter tolerances within one one-thousandth of an inch.

For most converting operations, rollers must have very exact dimensions to function properly. With over 40 years of experience, Menges can remove the old finish and apply new chrome, all while delivering exact diameters.

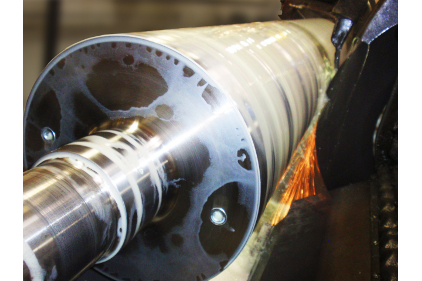

The re-chroming process

Before applying new chrome, the old chrome must be carefully removed using a precision grinding procedure. The worn chrome must be carefully but completely removed, but the roller’s outside shell must not be reduced in diameter. Very small tolerances in the thousandth of an inch range must be monitored.

After preparation and inspection, new chrome is then applied to the roll using advanced plating technology. The chrome’s thickness, layering specifications and other properties are very important, and each roll is different.

After the chrome is applied, it must be polished. Measured using “Ra value” (roughness average), the lower the Ra number, the shinier and smoother the chrome will be. Menges will offer a complete range of polish options, from standard mirror finish to optical mirror finish, delivering Ra values as low as 1-2 Ra.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!