Pharmaworks and Serpa Partner to Develop New Blister Transport System

Courtesy of ProMach

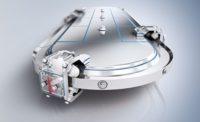

Pharmaworks and Serpa, both ProMach product brands, will introduce the new, fully-integrated BTS blister transport system at Pack Expo Las Vegas this upcoming September. Ideal for pharmaceutical, biotech, nutraceutical, medical device and other products, the BTS seamlessly transfers blisters from a Pharmaworks blister machine and collates them to feed a Serpa cartoner. Handling a wide range of blister format sizes and collating up to ten blisters per bucket, the fully servo-driven BTS achieves high speeds up to 500 blisters per minute while offering extreme flexibility and fast, repeatable tool-less changeovers.

“Transfer points are one of the most challenging aspects of any packaging line. To avoid the time, money and headache spent buying separate systems and integrating them in-house, product manufacturers and contract packers are increasingly turning to one-stop-shop equipment suppliers that can offer turnkey lines at lower costs and with faster delivery times,” said Aaron Metzler, Director of Sales and Applications at Serpa. “Although ProMach Pharma has offered standalone blister transport systems for many years, this is the first one that draws from the deep expertise of both the Pharmaworks and Serpa brands to offer complete integration.”

“Our sister-company Serpa led the development of the fully-integrated BTS, starting with Pharmaworks’ existing, field-proven blister transfer technology and then taking it to the next level by incorporating new innovations that perfectly synchronize these three machines, even at the highest speeds,” said Ben Bower, Vice President and General Manager of Pharmaworks. “With electronics, servos and more controlled directly by the cartoner, this transport system hugely simplifies line installation, operation and maintenance for the customer.”

Designed to be compatible with virtually every Pharmaworks blister machine and every Serpa cartoner, this transport system is available with intermittent-motion operation (BTSi) or with an oscillating wheel for continuous-motion operation (BTSc), depending on the application.

As blister packs exit the Pharmaworks blister machine, the BTS overhead vacuum transport system transfers single blisters into a magazine for buffering to accommodate fluctuations in speed between the blister machine and cartoner, maximizing line output. From there, the BTS will count out the proper number of blisters per cycle, depending on programming, to the cartoner infeed bucket.

Suitable for a wide variety of blister format sizes and materials, the BTS can transport blisters of tablets, capsules, softgels, vials, syringes, liquids and medical devices as well as consumer goods like cosmetics and batteries. Backed by Serpa’s proprietary Verified Changeover technology, the BTS offers easy and repeatable recipe-driven changeovers that can be completed in just a few minutes with no tools. To ease use, the BTS is controlled by the Serpa cartoner’s PLC and HMI.

Fully integrating with the Pharmaworks blister machine and Serpa cartoner, the BTS offers customers more reliable and repeatable performance with simpler installation, operation and maintenance, compared to equipment purchased separately. All three systems can be installed in a single room to minimize floorspace requirements, or primary and secondary packaging can be separated by a wall with pressure-controlled air flow.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!