New Products & Materials

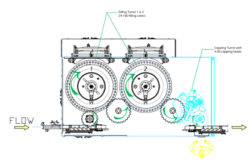

Twin filling bowls allow for higher production rates

Fogg Filler develops filler with two bowls to maximize capping capcity

April 15, 2013

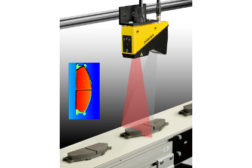

Hot melt system for case and carton sealing applications launches

InvisiPac designed to improve uptime and deliver cost savings

April 12, 2013

Packaging line improvements keep craft brewer focused on the future

Goal of increasing throughput while eliminating packaging breakage

April 5, 2013