Prepared Foods

Automation

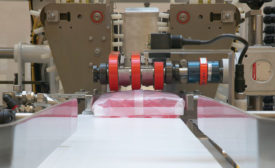

7 Tips for Choosing Cleanable Packaging Equipment

Machines incorporating sanitary design can improve the bottom line by lowering the risk of product recall and improving productivity.

October 15, 2019

Machinery

6 Factors to Consider When Designing a Cartoning Line

To find the solution that best meets your needs, ask the right questions.

October 15, 2019