OEE and Beyond: The Case for a Multi-Metric Approach

Overall equipment effectiveness is one tool in an overall suite of metrics that will allow a comprehensive view of a manufacturing operation.

Modern manufacturing environments produce an enormous amount of data. And as systems and platforms develop to monitor and manage this volume of information, many companies are left wondering what kind of software best suits their need for both measurement and analytics. One popular metric used in measuring manufacturing performance is Overall Equipment Effectiveness (OEE). In OEE, production performance is measured by calculating the factory’s performance, availability and quality. But as companies seek the best software solution for their data flow, they should consider if this metric is best suited for their needs and what other metrics are available.

OEE is a good metric for showing what happened at the shop floor level specific to machine performance and quality. It is very manufacturing specific but allows you to determine which machines or processes are performing in a less than optimal manner. It also reflects quality loss, again allowing you to focus on which equipment or system requires action for improvement. With software that allows exact measurements of these variables, preventive and predictive maintenance can be honed to reduce quality fallout and unplanned downtime. And, for issues identified as cycle time failures for operator and technician functions that exceed the established time in the availability calculation, training and process improvement initiatives can be undertaken to reduce downtime that impacts availability.

Is OEE the Best Metric?

But is OEE the best metric for measuring manufacturing performance? While it is a useful metric in the production process, it may well be that it is best thought of as one tool in an overall suite of metrics that will allow a comprehensive view of a manufacturing operation. To understand what other measurement tools are available to round out this “tool belt,” here are a few other metrics to consider:

Overall Operational Effectiveness (OOE): Overall Operational Effectiveness varies from OEE in how availability is calculated. With OOE, availability isn’t just Actual Production Time over Scheduled Time as in OEE. In OOE, availability is measured as Actual Production Time over Operating Time. OOE takes all operating time into account and can offer additional insights beyond OEE. This allows OOE to be used to identify areas for improvement in downtime from shift to shift or day to day and helps factor in variations from shift to shift or day to day performance. From this, labor, overtime planning and training issues can be identified and mitigated through response.

Total Effective Equipment Performance (TEEP): Another valuable metric to consider is TEEP. The distinction between other metrics is again in how availability is measured. In TEEP, availability is measured in Actual Production Time over All Time. TEEP is particularly useful in identifying what is called the “Hidden Factory” by showing what capacity is available with current equipment. The value of TEEP can help companies who need to understand their capacity and utilization of existing equipment. It can impact sales to prevent overbooking the factory and it can impact C-level decision-making to help plan capital expenditure plans and determine when, or if, new equipment is required.

Manufacturing Cycle Time (MCT): MCT measures how efficient a production operation is by measuring the time required to assemble, inspect, stage and convert materials and components into delivered finished products. Using this metric over time can help manufacturers manage the shop floor related to supply chain readiness. It is also useful for production operations that have numerous subassembly processes, blending, mixing or other labor intensive or value-added steps that occur in the production flow in conjunction with automated production equipment. As a result, it is highly useful for Make to Order (MTO) and Assemble to Order (ATO) production environments.

Limits to OEE as a Stand-Alone Metric

Any software investment must be measured by its usefulness to the enterprise. As a tool for measuring, understanding and improving performance, OEE is highly valuable. But by itself it can be limiting for several reasons:

It is Manufacturing Specific: While OEE is an excellent high-level metric, its specificity to manufacturing limits its utility for assessing the impact of other variables as it is disconnected to other upstream and downstream KPIs outside of manufacturing. Variables such as supply chain, inventory management and seasonal disruptions are often tracked with other software or manually through other means at the enterprise level. As a result, these may show up as an improvement or a drop in OEE that is unrelated to ongoing manufacturing improvements.

It is Resource Intensive: While OEE software can measure the inherent variables, managers and other decision-makers need to develop the improvement initiatives to improve each area. In and of itself, this is doable. But when viewed from a high level, the skillsets needed to introduce improvement initiatives (industrial engineers, project managers) are often engaged in other projects outside manufacturing that have been identified by C-level managers and other executives as higher priority. Looking only at OEE may reveal little or only incremental improvement, while inclusion of other metrics may reveal that these initiatives in other areas are bearing fruit even though impact to OEE is minimal or incremental.

It Can Become a Catch-All: It is common for companies to become focused on a single metric as an indicator of success. And with direct labor costs and equipment expense in terms of maintenance on the rise, OEE as a single metric runs the risk of being too narrowly focused. Using only a metric measuring scheduled time, factors such as shift performance, overtime impact, seasonal impact, supply chain disruption and other variables justify using OEE as one of several metrics and not as a stand-alone.

Production Methods, Pricing and Business Model

The effectiveness of OEE can be impacted by additional factors as well. One such factor is the method of production. Its effectiveness can be impacted by companies that utilize Make to Stock (MTS) compared to those who utilize MTO and ATO. As a result, the way OEE is calculated may be different depending on which production method is employed. While MTS manufacturers may use highly automated equipment on a 24/7 operation to produce a commodified product, MTO and ATO manufacturers may have numerous subassembly processes, inspection points, customization points such as painting or packaging, and other variables. These will impact the overall effectiveness of OEE depending on how it is calculated.

A second factor impacting OEE effectiveness depends on the market reality and pricing strategy of the manufacturer. If a producer is in a highly competitive high-volume market where margins are low, goods are commodified, and the enterprise must use cost plus pricing, the OEE metric may be viewed as more critical for success. However, in higher margin products where producers use competitor pricing, value is defined differently, and idle or intermittently operated equipment may be the norm. As such, other metrics must be considered in addition to OEE when measuring performance.

A final factor that could impact the use of OEE as a stand-alone metric is the type of business model used. Again, in a commodified product where direct labor and materials account for most of the cost, OEE is highly valuable for identifying areas for cost improvement. However, seasonal producers as well as ATOs may incur costs for flex labor, seasonal labor, higher overtime or subcontracted labor and production that is as much a concern for executive managers in terms of cost as is “regular” production. The use of additional metrics here too would be necessary.

A Mix of Metrics

Manufacturing is a complex endeavor that doesn’t fit single category or method of production. Therefore, using a single metric such as OEE as a standard may not be an effective way to manage improvement. And any software purchase should reflect this reality as well. A better path would be to incorporate software that allows a mix of metrics to be used as part of a comprehensive decision-making strategy for improvement.

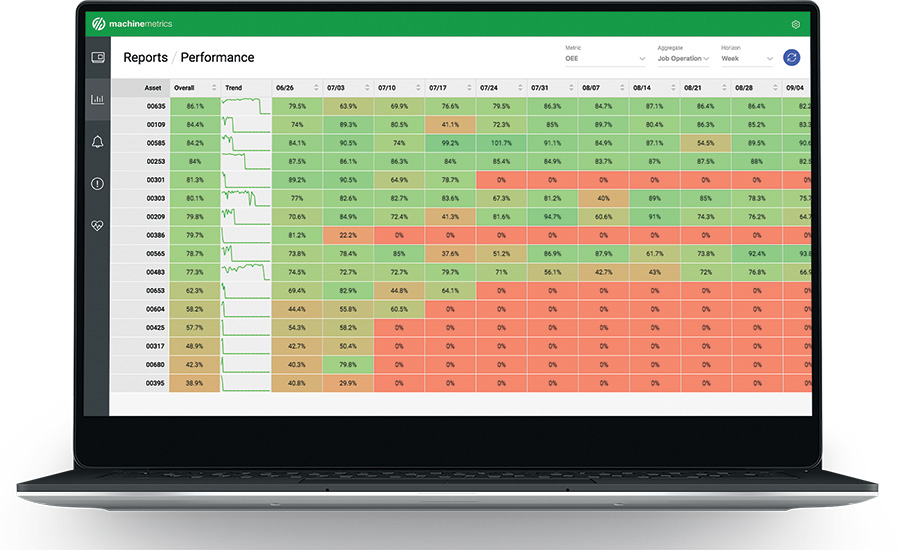

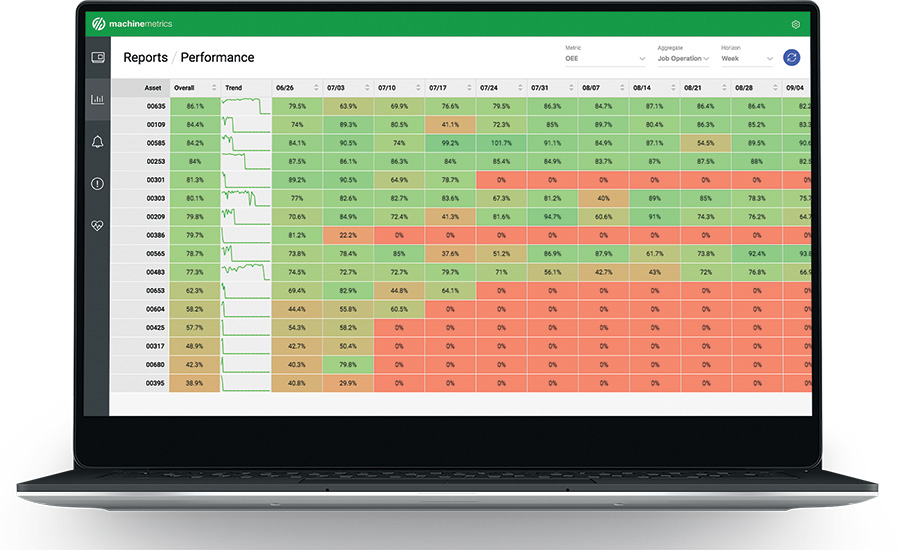

The ability to visualize production in a mix of metrics can allow companies to act on the realities that affect the entire enterprise. This visibility can improve overall efficiency by as much as 20%. Coupled with real-time monitoring, the right software can give companies the power of machine-specific data used in OEE to manage equipment assets and develop predictive maintenance programs with real-time alerts, calls to action or deep analytics to spur additional improvement. Yet, it can also deliver the broader understanding of performance for metrics such as OOE and TEEP to allow better labor and shift planning, training and management at a local level while empowering high-level managers with tools to understand manufacturing performance at the global level for issues such as supply chain and capex planning.

Combined with deep analytics to analyze issues trending from all metrics, managers would have a view into all variables impacting production. And when integrated into a manufacturers existing ERP system, these metrics can be tracked to help identify bottlenecks and measure improvements across the enterprise.

MachineMetrics is an award-winning manufacturing analytics platform for discrete manufacturers. The company’s Industry 4.0-ready solutions work out-of-the-box to increase productivity through edge connectivity, real-time visibility, deep manufacturing analytics and AI-driven predictive notifications. machinemetrics.com