Cover Feature: Films for Food Packaging

A Flexible Films Guide: Various Choices for Food Packaging

Choosing a food packaging film today is a complicated process, even for seasoned converting and packaging design professionals. A newcomer to the field or a packaging student, who might be inclined to seek insight from a search engine, would be buried in seconds in a blizzard of global information. The ultimate question is: Why might one film type be a better choice rather than another when considering packaging structures, lamination design and end use?

PET, BOPP, CPP, MetPET, MetOPP – there’s an alphabet soup of film choices available. When entering into a dialogue with a customer about choice of film, it’s critical to ask specific questions and listen carefully for the functional performance the application requires. Then we can begin to determine whether BOPP, PET, metallized, clear, matte or a combination of films is the right solution.

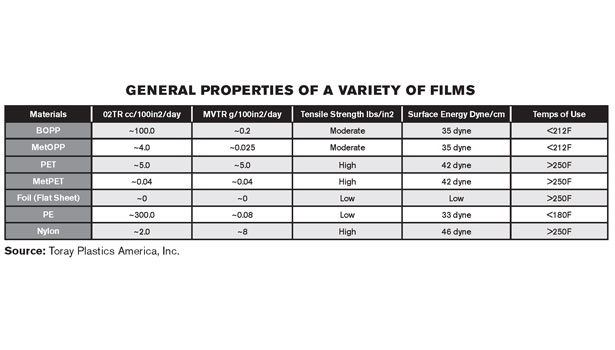

Aside from the obvious question – What is the application? – we’ll want to explore with the customer FDA compliance, economics and yield requirements, the equipment to be used, targeted line speeds and processing temperatures and conditions. What about the barrier level required? Must it be very good, superior, or somewhere in between? Is moisture barrier of greater concern than oxygen barrier, or are they of equal importance?

We’ll also want to define other application processing characteristics, like co-efficient of friction, which can contribute to more efficient processing and packaging manufacturing. Sealability (cold-seal or heat-seal) is also vital. The seal affects manufacturing speeds, shelf life, the appearance of the package, the consumer’s ease of use and even how the package travels at different altitudes.

Then there are aesthetic, branding and marketing requirements, which bring haze, clarity, gloss and printability into consideration.

BOPP v PET

Exploring the similarities and the differences between BOPP and PET, we know that both have been around for decades and have evolved a lot. Today, you can find them at varying levels of technological sophistication.

PET typically offers excellent oxygen barrier and moderate moisture barrier. It’s usually stiffer than BOPP and has superior optical qualities. It exhibits good resistance to oil and acidic product contents, whereas BOPP is more likely to absorb and become distorted by those substances. PET is a very stable film, which means it shows less stretching during the printing and laminating processes. It is also known for its excellent thermal stability (the ability to withstand high temperatures during processing) and superior melt temperature that makes it the go-to solution for ovenable food applications, like the need to withstand microwaving or heating in a conventional oven. In terms of mechanical properties, such as modulus and tensile strength, PET typically outperforms BOPP.

Basically, PET is well suited for applications requiring a strong film with high tensile properties, scuff resistance and durability.

By comparison with PET, BOPP film offers an improvement in moisture barrier. Converters and end users often select it for use as a print web, an inside barrier web, or a sealant web in a bag or pouch lamination, or as an HFFS wrapper, for salty snacks, baked items, crackers and cookies. It also takes center stage with its low SIT (seal initiation temperature), superior seal performance and lap seal capability. A low SIT enables increased production throughput.

Cast PP, or CPP, is a very soft, tear- and puncture-resistant film and has high seal-strength and high burst-strength properties. CPP also has good heat resistance so it’s a desirable candidate for use in hot-fill or retort applications.

It’s important to remember that the packaging films we are discussing are multi-layered and have varying skin and core designs created to achieve specific functionalities. By engineering film skin layers, or “dialing in” unique functionality for a broad range of end use applications, the barrier, sealability, appearance, feel and printability of most films are customizable.

Metallizing Films

Transforming PET and BOPP into a metallized structure changes the game even more. Metallization significantly impacts the oxygen and moisture barrier, makes for an opaque barrier to light, offers a high-reflective glossy aesthetic and opens up new packaging application options, like those where foil might be the traditional choice, for example.

If we compare MetPET with MetOPP, we find that MetPET has superior oxygen barrier and good moisture barrier, but the MTVR is still inferior to MetOPP. However, MetPET’s bond strength and the general robustness of a lamination are superior to those associated with MetOPP.

MetPET is excellent for replacing foil in a lidding application for dairy foods, like yogurt or ice cream, or for items like applesauce or puddings. In comparison with foil, it offers better economics, improved barrier durability and superior puncture resistance.

MetOPP has excellent moisture barrier, very good oxygen barrier, barrier to light, a highly reflective gloss and better puncture resistance in relation to MetPET and foil, and excellent flex-crack resistance –all of which can be achieved at a relatively low cost. It tends to be popular for nutritional bars and higher-end snack food packaging applications.

MetOPP is often designed with a low SIT heat seal layer, allowing it to be used in a two-layer lamination. MetPET doesn’t always have this type of heat-seal functionality and is often utilized in a triplex laminate.

Key Trends

There are several trends that are driving changes in packaging today and affecting film selection. Clear product visibility is a key driver of change. The consumer’s expectation is that the food they’ve purchased is made with fresh ingredients, and visibility offers some assurance. Artisanal products continue to gain favor with the mass market and niche customer, and both groups are driving the trend toward clear packaging. Creating a package that is easily opened and resealable, is also a driver.

Maximizing shelf life continues to be of critical importance with the ongoing expansion of global distribution channels. Barrier to oxygen, moisture, light and contaminants are key performance requirements for optimal product shelf life. Package designs vary from flat bottom bags to standup pouches to pillow packages to rigid containers with high-barrier lidding.

The CPG wants to prevent fats, oils, and vitamins from oxidizing; prevent water absorption that makes food soggy or water depletion that dries out food; and prevent photolytic reactions, which can lead to the deterioration of fats, vitamins, flavors and other ingredients. Look for hermetic sealability to further improve shelf life.

Aesthetics are also driving change. Matte finishes, a soft feel and sophisticated print designs are increasingly popular.

Bio-based polymer technology continues to be a very exciting area. The research and development on bio-based films is very much alive and will continue to expand. Feedstock options are still evolving. In terms of the yield and economics of a bio-based OPP or PET film, it’s still higher than with regular film and must come down.

Cost Considerations

There’s no getting around cost as a primary influence in the choice of a film. It’s important to think holistically about “package economics”—the total cost to a customer for creating a package lamination structure. In a cradle-to-grave approach, we start with resins and consider the total cost of supply through consumer use and disposal.

There may be higher costs per one pound of packaging film, but by looking for efficiencies or gains during converting, packaging, distribution and point-of-purchase, it’s possible to achieve an overall cost-savings.

There are many ways to reduce the total cost, such as examining manufacturing, supply chain and operation efficiencies. One major way to reduce the cost of a packaging structure is by using a thinner gauge film, also known as downgauging.

Having more film footage per roll means that the customer needs fewer rolls, and that in turn means there are fewer roll changes and less waste, fewer pallets used and fewer trucks on the road, so the customer’s costs for delivered finished goods are further reduced. You could take that information to the next level and even calculate CO2 reduction.

In general, without performance-value barrier coatings or metallization, BOPP is typically less expensive than PET. Cost is also affected by the quantity purchased, the constant fluctuation of raw material costs and the location of the supply source.

If the converter says his most important goal for the package design is extended shelf life, we know the focus is going to be on protection against moisture, oxygen, outside contaminants and light. So barrier attributes will be a primary consideration to meet that customer’s needs.

Toray Plastics (America), Inc.

www.toraytpa.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!