UTECO ConverDrome® to Showcase ESI's FlexoBeam® on EB CI-Flexo Press

Energy Sciences Inc. (ESI) is a proud partner with Uteco Group at their new, state-of-the-art ConverDrome® in Verona, Italy. This technology center will showcase the latest developments in printing, converting and other advanced applications fields.

The center will offer an advanced EB CI-Flexo press equipped with a FlexoBeam® Electron Beam (EB) from ESI. This is the ultimate EB technology for flexible packaging converters. Designed specifically for CI-Flexo presses, the FlexoBeam® has the smallest footprint and lowest profile for new or retrofit installations.

EB CI-Flexo is a natural fit for wide web CI-Flexo printers who want to maximize production, reduce downtime, and create value for customers.

EB CI-Flexo is Clean, Green and Ultra-High Resolution

The new Uteco EB CI-Flexo press at the ConverDrome® will be able to demonstrate multiple new EB CI-Flexo ink technologies. In addition to significant saving in energy and ink costs, EB CI-Flexo allows printers to achieve better print quality in demanding food applications all while reducing or eliminating VOC emissions.

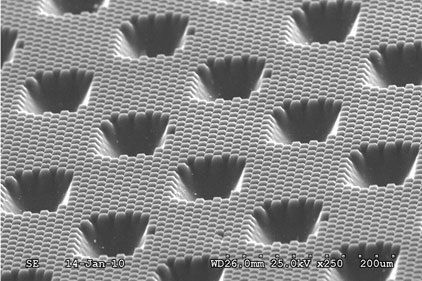

EB Flexo delivers on many dimensions of quality. There is better image quality, with 70 lines per centimeter (180 lines per inch) allowing stochastic FM screening and enabling high fidelity, continuous tone images that exhibit fine detail. And the smaller dots stay small because there’s less dot gain due to the ultra-high solids content of the inks, extending the color gamut. In addition there’s the flexibility which comes with being able to print quality images on various substrates, from thin gauge films all the way to uncoated papers and boards due to the high solids inks not diving into the substrate.

But EB CI-Flexo’s best dimension of quality is its consistency—on both long and short runs. The high solids inks maintain their viscosity better in the pans. And because of the nature of the inks there’s less dry-in on the anilox rollers and less cleaning of plate rollers mid-run. Inks can also be left in the pans overnight. All this leads to higher consistency, less waste, less downtime, increased throughput and greater productivity.

In addition to curing inks on EB CI-Flexo presses, EB is used in flexible packaging to cure EB Coatings, EB Over-Print-Varnishes, and instant-cured 100% solids EB Laminating Adhesives.

Book your trial NOW

As with all new technology there’s risk. And it’s always best to work with the leaders. Uteco and ESI, through their shared experience and investment commitment, have the knowledge, resources and people to answer all your questions, solve your problems, and get you to market fastest. Both firms can point to recent EB CI-Flexo customer installations as proof of the commercial viability of this process.

The New Centre of Excellence ConverDrome® will be inaugurated at the end of October 2014, ready for live demonstrations 4th quarter 2014.

Contact ESI for a trial—Call, Click, Connect:

978-694-9000 | sales@ebeam.com | www.ebeam.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!