Menges Roller Co. Expands Design and Engineering Capacity

Menges Roller Co. has increased its capabilities for modeling temperature and performance of rollers

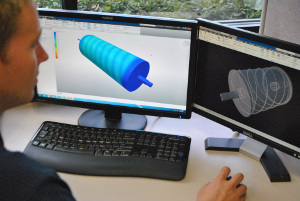

Menges Roller is pleased to announce the enhancement of its Engineering Department capabilities. Using advanced technology, Menges Engineers can now see and predict the exact temperature a roller will achieve and how that temperature will affect the web – all before the roller is built.

Menges Roller is pleased to announce the enhancement of its Engineering Department capabilities. Using advanced technology, Menges Engineers can now see and predict the exact temperature a roller will achieve and how that temperature will affect the web – all before the roller is built.

Heat transfer rollers are a flagship product at Menges, and these Engineering enhancements are primarily aimed at the heat transfer roll marketplace. These advancements will help Menges Roller continue designing rollers that perform specific tasks at very specific temperatures.

Utilizing the latest Computational Fluid Dynamics (CFD) technology, Menges Engineers compute all the relevant factors – substrate types & dimensions, linespeeds, thermal transfer fluid data, roller dimensions, flowrates, and so on – to see the temperature & thermal profile of a roller before it is built.

Matt Menges, president of Menges Roller, explains, “With modern converting applications, heat transfer rolls must perform at a very high level…and we take pride in building some of the best heat transfer rolls on the market. With these Engineering enhancements, we’re simply continuing on that path. Now, instead of just seeing static roller dimensions, we can demonstrate how changes to those dimensions affect the flowrate, the roller’s temperature, the web’s temperature, and the entire converting process. It’s all about designing custom rollers that perform flawlessly in their application.”

As part of these Engineering Department enhancements, Menges has also invested in technology that allows engineers to model weight and load-bearing characteristics. This allows engineers to compare the strength & stress capacities of various steels in relation to roller design and component dimensions.

Menges Roller Co.

(847) 487-8877

(847) 487-8877

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!