PACK EXPO: Show Issue, Part 1 of 2

Pack Expo Show: Viva Las Vegas

Designed to power innovation across the industry, PMMI’s PACK EXPO Las Vegas and co-located Healthcare Packaging EXPO, Sept. 23-25, will cover 900,000 net sq. ft. of exhibit space, with 2,000 exhibitors and 30,000 attendees from nearly every market.

Here are just some of the stops, networking opportunities and educational formats at this year’s event:

Robots Taking Over

NEW! The Robotic Zone: A new sight this year, the Zone covers robotic activities and cobot display. You’ll be greeted by an Omron Robot Greeter (how cool is that?). The interactive experience allows visitors to see first-hand how innovations in automation are transforming the industry.

Attendees will see robots playing piano and bowling, interactive dice playing cobots, Comau’s interactive wearable exoskeleton (as seen at last year’s PACK EXPO International) just to name a few. Local robotics teams will be displaying their robots in action in the Future Innovators Robotics Showcase. North Hall

Pavilions

NEW! PACKage Printing Pavilion: After a successful launch in 2018 at PACK EXPO International, this pavilion will focus on the advantages of digital printing showcasing the latest in cost-effective solutions for smart, short-run, on-demand, cost-effective, variable data and personalized packaging. Central Hall

Containers and Materials Pavilion: This pavilion features the latest innovations in glass, paperboard, metal and plastic. With sustainability a top concern, many options will be on display. The pavilion, sponsored by Dow Chemical Company, will also feature the Showcase of Packaging Innovations, highlighting award-nominated packages. Lower South Hall

Confectionery Pavilion: For attendees in the candy and other sweets markets, see the newest trends in aeration, batch refining, shaping, cluster production, cooling conveyors and more. Sponsored by the National Confectioner’s Association (NCA), the pavilion will also showcase easy-open packaging and portion control options. South Upper Hall

Reusable Packaging Pavilion: This pavilion will have the newest and greatest solutions for increasing sustainability across the supply chain. Inside the pavilion, the Reusable Packaging Learning Center will offer free expert and end-user presentations on best practices. Sponsored by the Reusable Packaging Association (RPA). South Upper Hall

Lounges

Take a break at one of these industry-specific lounges to relax and network. Lounges are great for casual meetings with peers. They also offer free educational presentations by industry experts.

The Candy Bar Lounge: For those in the confectionery market and their customers. Hosted by the NCA and sponsored by Bosch. Join the reception on Tuesday, Sept. 24, from 3:30-5:00 p.m. Upper South Hall, #US-7201

The Beverage Cooler Lounge: Serving the beverage industry, this lounge will offer up a meeting spot for Upper South Hall, #US-7629

The Snack Break Lounge: Visit with like-minded snack industry professionals at this central hub. Hosted by SNAC International. Upper South Hall, #US-7628

Excellence in Technology

NEW! The Technology Excellence Awards: Another first for the Las Vegas event, the awards will recognize exhibitors’ innovative technology that has not yet been shown at a PACK EXPO and Healthcare Packaging EXPO in the previous calendar year. All registered attendees will be able to vote on their favorites among the finalists selected in specific market segments.

Networking Events

NEW! CareerLink LIVE: CareerLink, PMMI’s online job board, is also going live for the first time in Vegas. CareerLink LIVE@PACK EXPO is an opportunity for PMMI, CPA, IoPP members and consumer packaged goods (CPG) companies to meet with students and veterans pursuing careers in packaging and processing during one-on-one informational interviews. Interviews will take place at the show and registration is $49.

Packaging & Processing Women’s Leadership Network Breakfast: Launched in 2016, PPWLN serves to recruit, retain and advance women in processing and packaging. Ellen Ochoa, the first Hispanic woman to ever go to space, is the keynote speaker at the breakfast. Tuesday, Sept. 24 at 7:30 a.m. Register at pmmi.org/womens-leadership-network/events.

Education

In addition to many exhibitors offering booth presentations, The Innovation Stage, The Forum and presentations in the Reusable Packaging Learning Center are free of charge.

NEW! The Forum

Also new this year, The Forum offers learning opportunities, including free 45-minute sessions, small groups, hands-on activities and Q&As daily. Monday and Tuesday 10:30 a.m. – 4 p.m. and Wednesday 10:30 a.m. – 2:15 p.m.

The Forum Sessions are led by:

- OpX Leadership Network

- Contract Packagers Association (CPA)

- Institute of Packaging Professionals (IoPP)

- The Organization for Automation and Control (OMAC)

- Robotic Industries Association (RIA)

- World Packaging Organization (WPO)

- PMMI University

- PMMI Business Intelligence

INNOVATION STAGE

The 30-minute Innovation Stage is the place to learn about recent breakthroughs and best practices by packaging leaders. Covering a variety of subjects, the Stage is open Monday and Tuesday, 10 a.m. – 3:30 p.m. and Wednesday, from 10 a.m. – 12:30 p.m.

GIVING BACK

PACK for a Purpose: Robots Fighting Hunger where robots will be packing food into backpacks to feed children on the weekends, in collaboration with Blessings in a Backpack. Exhibitors in partnership with Allied Technology will supply robots for this cause. Robotics Zone, North Hall.

PACK gives BACK: The annual benefit will feature the legendary Steve Miller Band. With hits like “Jet Liner,” “The Joker,” “Take the Money and Run,” “Fly Like an Eagle,” and “Jungle Love,” it’s sure to be a hit — and for a great cause. A portion of the proceeds will support NS2 Serves, a nonprofit dedicated to helping recent U.S. military veterans transition from combat boots to business suits. Rockwell Automation returns as the title-level sponsor of this year’s event. Register at packexpolasvegas.com/pack-gives-back.

|

Exhibitor Innovations Here are some innovations attendees will discover at PACK EXPO Las Vegas. Make sure to stop by as you make your way around the show floor. Combo Machine Combines Flowpacker and Pickerline

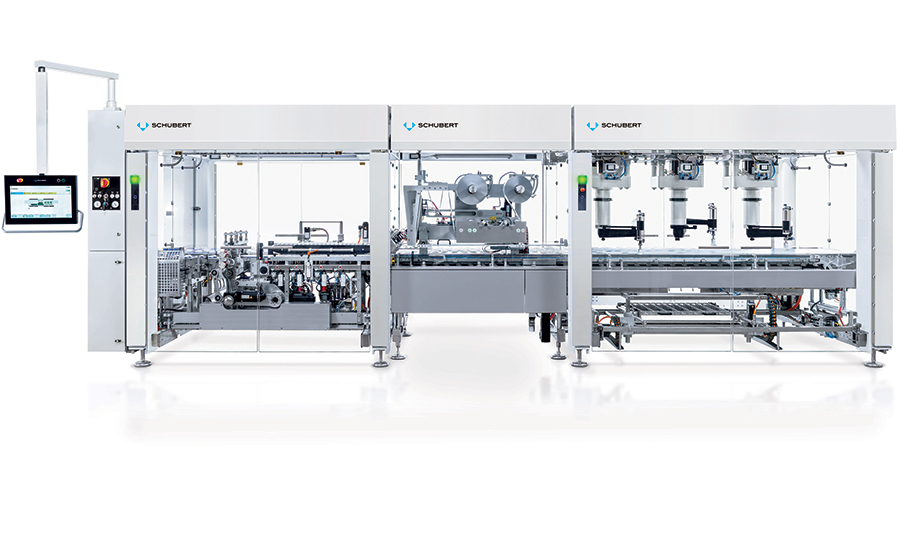

The Schubert Group’s (booth US-7649) new lightline flowpacker will be on exhibit, showing a combined flowpacker and a pickerline in a single system. It features Schubert’s patented sealing technology for packaging heat-sensitive products even more gently into flowpacks. The exhibition machine, offering a higher degree in compactness, will be installed at a North American baked goods manufacturer after the show. Schubert’s lightline machine series includes three compact preconfigured packaging machines: the lightline cartonpacker for erecting, filling and closing cartons, the lightline pickerline and the lightline flowpacker. Vision-Guided Cartoner Handles Wrapped, Packaged Products

JLS Automation (booth LS-6135) is displaying the next generation of carton loading — the Peregrine robotic cartoning system. The vision-guided Peregrine cartoning system made with a distinctive and unprecedented construction. This high-speed system easily loads flexible bags, flow packs and other primary packages into tri-seal and other style cartons. In addition, the flexible system minimizes changeover while meeting production needs for small batches. The Peregrine is ideal for several markets, including bakery and snacks, confectionary, frozen foods, prepared foods, protein and ice cream treats. Flexible Conveyor Platform Moves in Various Ways

Dorner’s (booth C-1844) FlexMove conveyor platform makes tight turns in and around existing equipment. The flexible chain conveyors are designed for effective horizontal and vertical product movement capabilities when floor space is limited. FlexMove conveyors are engineered for numerous applications. FlexMove conveyors allow for horizontal turns and elevation changes on a continuous run driven by a single gearmotor. Helix and Spiral styles feature continuous 360˚ turns for moving product up or down in a vertical space; Alpine design features long inclines or declines with tight turns; Wedge design conveys a product by gripping the sides; and Pallet/Twin-Track Assembly works by moving the palletization of products with similar sides. Compact Labeler Designed for Pharma Industry

HERMA US Inc. (booth N-310) will introduce a new ultra-compact labeling machine at Healthcare Packaging Expo. The semi-automatic HERMA 211 HC wrap-around labeler was designed to meet pharma sector demands for a fully FDA-compliant labeler in a compact footprint. It is particularly helpful in the transition from clinical trials to full production, as well as for the smaller-batch manufacturing typically found in biopharmaceuticals settings. The HERMA 211 HC is suitable for labeling a wide range of cylindrical products including syringes, tubes, glass vials and ampoules. Capable of applying approximately 30 labels per minute, the HERMA 211 HC can handle webs as wide as 80 mm, and products ranging in diameter from 10-120 mm. Sustainable Packaging Reigns Supreme

TC Transcontinental (booth LS-6701) will display its many sustainable flexible packaging offerings. The company recently won the entire Sustainable Packaging category at the 2019 PAC Canadian Leadership Awards with the Harney & Sons Fine Teas and Les Aliments Jardi 100% recyclable packages with barrier. TC Transcontinental Packaging is creating fresh, sustainable, innovative packaging products that meet the industry’s growing demand and inspire consumers. On day one of the show, the company will be revealing new brands and logos that represent its entire recyclable and compostable portfolio. Rotary Filler with Hygienic Design

Spee-Dee Packaging Machinery (booth C-3436) will display the open, accessible design of its rotary dry product filling system. The machines feature a tool-less design for simple changeover. Filling funnels include a patented magnetic connection that eliminates the use of fasteners to further reduce changeover time and improve cleaning. Container adapters are changed to quickly set up for varying heights and shapes. Vibrators help settle the product into the container and optimize headspace. The reduced footprint provides easy access to the machine, which features full-length doors. Servo drive augers raise, pivot and lower outside the guard to improve accessibility from the floor level. The filler comes in optional stainless steel for long-lasting durability and a more hygienic machine. Checkweigher Is More Robust and Easier to Use

The Thermo Fisher Scientific (booth C-2200) Versa Flex FR44HD is a powerful checkweigher designed for the packaged food, pharmaceutical, warehouse and personal care industries. It now includes stainless-steel construction, a heavy-duty drive and enhanced user interface. New features and benefits of the Versa Flex FR44HD checkweigher include a heavy-duty drive, standard across all FR44HD models for rugged performance, increased uptime and productivity; reliable handling of loads up to 110 pounds with speeds that can exceed 300 feet per minute; a new control system for improved user navigation; and more. The Versa Flex FR44HD checkweigher is also available in a warehouse version. Continuous Inkjet Printer with Improved Performance

Videojet (booth C-2006) will showcase the Videojet 1580. Designed to deliver improved printer performance and operator effectiveness, the 1580 continuous inkjet printer offers simple operation, reduced maintenance and superior print quality during everyday operation. The printer utilizes consumption data to assess and suggest improvements on how the printer is used, helping to reduce total cost of ownership. The SIMPLICiTY user interface reduces operator printer interactions, helping to eliminate potential user errors through a 10-inch touchscreen display. Users can run longer without intervention with optional CleanFlow technology, designed to provide maximum uptime without the need for plant air. Paperboard and Packaging Design Innovations

On the exhibit floor, Metsä Board (booth LS-6638) will highlight its range of packaging analysis and design services that encompass material and structural evaluation as well as modification of existing packaging. Together with its lightweight paperboards, Metsä Board’s packaging analysis and design service enables better, safer and more sustainable packaging solutions. The exhibit will also feature an improved and sustainable folding boxboard portfolio; eco-barrier boards developed for food and food service packaging; the Better With Less Challenge submission info; new Excellence Center combining package design and R&D; and PackageLab that provides inspiration and ideas for materials innovation. Smart Camera System Inspects Labels, Codes in Wet Environments

METTLER TOLEDO (booth C-2023) CI-Vision is introducing the new V15 Round Line smart camera inspection system, designed to confirm the presence, completeness and readability of alphanumeric label information and printed 1D and 2D codes on round packaging such as food jars, cosmetics and household chemicals containers, and reject those not in compliance. Using six evenly distributed viewpoints and liquid lens focusing technology, the V15 conducts 360˚ inspections of containers to ensure both label ingredient information (such as potential allergens) and inkjet-printed codes are clearly readable. The liquid lenses adjust automatically to the distance from the target, enabling the system to inspect containers of different sizes without physically moving the cameras. Case Packers & Cartoners Feature Delta and Six-Axis Robots

PMI KYOTO Packaging Systems (booth C-4436) is showcasing its expanded robotic solutions. The company offers a wide variety of proven robotic packaging capabilities built for specific applications, including collation, product handling, case packing, carton loading, palletizing and more. To meet a variety of specifications, delta or six-axis robots are integrated with cartoners or case packers to provide pick-and-place capabilities as well as unmatched automation flexibility. PMI KYOTO’s high-quality vertical and horizontal cartoners, case packers and integrated packaging systems continue to provide high-quality and built-to-perform packaging solutions for the food, beverage, cosmetic, confectionery and pharmaceutical industries. Point-of-Purchase Display Capabilities

Glue Dots International (booth LS-6507) will demonstrate how versatile pressure sensitive adhesive patterns can be used as an alternative to double-sided foam tape and hot melt for point-of-purchase (POP) display assembly. Attendees can see how pressure sensitive adhesive patterns reduce labor while increasing efficiency, productivity and profits. With those features, a competitive edge can be gained with the use of Glue Dots’ hand-held applicators, including the Dot Shot Pro, Quik Dot Pro and 8100 adhesive patterns. Simple and easy to load, the applicators are durable enough to withstand any work environment and require little training. Glue Dots adhesives are instantly applied using the hand-held applicators, ensuring faster application than manually applied double-sided foam tape. Industrial Mezzanine for Added Office Space & Equipment Access

Wildeck Inc. (booth US-8420) will display an industrial mezzanine at this year’s event. The elevated platform can be used for storage, manufacturing, office space or as an equipment access platform. Within the packaging industry, the work platforms are the ideal place to store additional inventory, supplies and equipment. Constructed with heavy-duty steel, the free-standing structures can safely support tremendous loads, including industrial packaging equipment. Designed around a building’s existing blueprint, the nut-and-bolt construction of a Wildeck mezzanine provides for easy expansion and relocation (if needed). Depending upon a facility’s ceiling height, a Wildeck mezzanine can be single or multi-tiered, effectively adding a second or third level to an existing building. Latest OEE/Data Collection Software

Wintriss Controls Group (US-8460) will be showing the new ShopFloorConnect Version 6.0. ShopFloorConnect OEE and Shop Floor Data Collection Software collects downtime and production efficiency data from every machine in the manufacturing operation, displays it in real-time and produces manufacturing reports, including detailed OEE reports in a variety of formats. The software can significantly increase manufacturing capacity and profitability by identifying and quantifying excessive production losses and bottlenecks. ShopFloorConnect Version 6.0 has a new design format for fast, easy access to all data, offering several new features for more robust, user-friendly reporting and dashboard customization, flexible scheduling capabilities and machine interface enhancements. Users can now improve the OEE of their machines by tracking the reasons for scrap. |

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!