Cover Story: Flexible packaging

Flexible Packaging: growth, challenges and opportunities

Pouches continue to delight consumers.

According to Persistence Market Research (persistencemarketresearch.com), the global flexible plastic packaging market has witnessed healthy growth. As the study states, the global flexible plastic packaging market is projected to witness a high 6.7% CAGR during the period assessment of 2017-2022. This is primarily due to:

- The rise in population, especially middle class;

- The growing demand for flexible plastic packaging from the food and beverage industry. as well as pharmaceutical industry;

- A rising preference of convenient packaging and handling.

The food and beverage segment is expected to dominate the market by end-use category with a share of 67.4% in 2017.

The popular pouch

We know why everyone loves the pouch: They are lightweight, easy to store, carry and reseal, inexpensive, easy to transport and can be used to package a wide variety of products. They also support the shelf life of the product, create appeal, enable visibility of the products within and maintain product freshness.

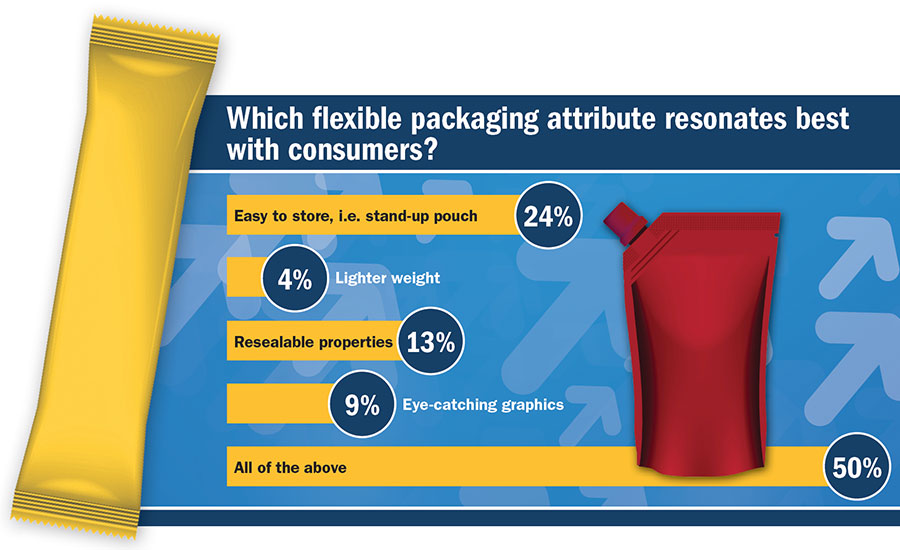

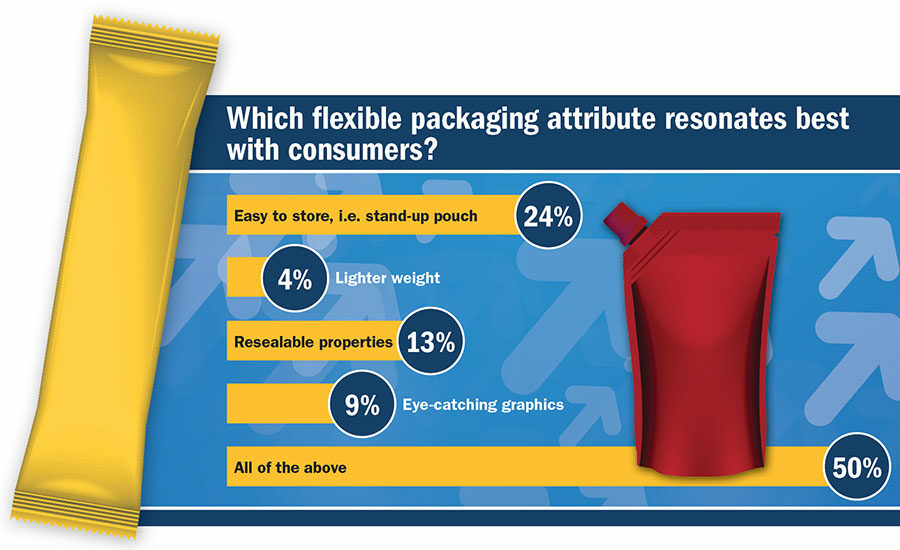

In fact, 24% of Packaging Strategies readers say that “easy to store” is the attribute that best resonates with them. However, 49% of readers say that a whole plethora of features attract them to flexible packaging, from easy to store, its light weight, resealable properties and eye-catching graphics.

More brands are launching products in pouches, as well as suppliers launching pouches to meet current challenges, offer solutions and to provide product protection.

Oracle Packaging (oraclepackaging.com) offers high-barrier pouchstock laminate tailored to the specific challenges of OTC effervescent products. Ideal for packaging coarse, often powdery effervescent tablets, the flexible packaging solution provides protection against moisture and oxygen for a variety of product formats, shapes and sizes.

How? A durable sealant layer used in the laminate provides excellent hot tack and hermetic seals at relatively low seal temperatures – important when packaging products with a powder residue. The pouching materials are comprised of layers of either ink or lacquer, and paper/PE/aluminum foil/sealant.

Offering high levels of puncture resistance, machinability and seal integrity, Oracle Packaging’s effervescent tablet laminates are available in 10 colors in both printed and unprinted rolls.

Roll that film

Another new product on shelf is a rigid container using a special film lid for easy snacking.

Created to tap into the growing on-the-go snack market, Parkside (parksideflex.com), a speciality packaging solutions provider, is launching a reclosable lidding film for a snack fruit pack.

The Handy Candy pack, which can contain either tomatoes, blueberries or an organic range of fruit, is comprised of a PET pot with a reclosable lidding film. The pack is a first of its kind in the U.S. and helps consumers eat healthier on the go.

“Our customer, Veg-Fresh, wanted to take advantage of the growing popularity and demand for convenience foods with a new fruit snack pot and approached us for our packaging expertise. Veg-Fresh had originally investigated label reseals and other reseal systems but given the size of the flange on the pot, the size of the opening and the circular shape, it was proving difficult. Our solution, which is similar to a yogurt pot type opening, ticked all their boxes. It was a seamless transition from their existing standard lid to our reclose lidding film,” says Pete Ford, new business development manager at Parkside.

The reclose lidding film, which includes an anti-fog coating, includes a patent-applied pressure-sensitive adhesive that has been specifically developed by Parkside.

What’s next for flexible?

Flexible packaging continues to reign strong and steady in the packaging realm. But where can the market go next, and what issues or materials are threatening its growth?

“Certain categories are beginning to mature, the growth in baby food and fruit puree have slowed but they are reaching the upper part of the S curve,” says Jon Pietsch, market manager, Bemis (bemis.com). However, “pouches still continue to grow year over year. New emerging processing technologies such as aseptic and HPP will open new categories for flexible packaging. The inverted pouch format will also expand into other product categories in both food and nonfood,” he says.

The segment is certainly growing, but that’s not to say that there are not also challenges to overcome.

“I believe the biggest challenge facing flexible packaging over the next few years is an increasing focus on recyclability. We are seeing growing pressure from retailers, brand owners and even state governments as they consider extended producer responsibility legislation that will affect products packaging in traditional flexible laminates,” says John Wilson, market manager, Bemis.

And while moving a loved product to a pouch may seem like a no-brainer, it is sometimes harder than one may think to convert a product line to a pouch over a rigid container.

“Large brands are a little more reluctant to switch over to new packaging formats because of their infrastructure of canning or bottling. It becomes difficult for them to consider transitioning. Whereas the emerging brands may start immediately in a pouch format and not even consider a can or a bottle,” says Mark Moorhead, market director, Bemis.

The opportunities are endless for small- and mid-sized companies to launch products in pouches to outshine legacy brands on shelf. Large companies have the opportunity, too, to reintroduce themselves in the fan-favorite pouch. With all of the attributes that resonate with consumers, retailers and packagers, the pouch continues to shine on shelf. But that doesn’t mean there may not be a strong competitor in the near future. Read my editor’s note on page 8 to learn about a new material threatening the pouch’s empire.

|

Chocolates over the holidays

You probably will be enjoying more chocolate than normal over the next few weeks as you celebrate the holidays. As more candy companies adopt flexible packaging into their line-up, look for chocolate and other candy items to be packaged in pouches for fun gift-giving or simply easy eating. Technavio’s latest report on the global chocolate packaging market provides an analysis of the most important trends expected to impact the market from 2017-2021. One to mention is that the use of flexible plastic is growing because of its lightweight properties, which result in reduced transportation costs, as well as reduced carbon footprint. Other advantages of flexible plastic are the reduction of energy required in the manufacturing process and minimization of landfill waste in comparison to rigid materials. Cacao Barry introduced a chocolate packaging bag which allows easy storage, reclosability and recyclability. These features attract retailers, consumers and packagers, alike. |

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!