Trends Driving Popularity of Flexible Packaging

Majority of Brands Using Flexible Packaging on Some SKUs

Flexible packaging is rapidly replacing solid packaging across the globe for all the good reasons – lower manufacturing costs, enhanced supply chain effectiveness, extended shelf life, light-weight, augmented sales, and greater consumer appeal.

The tag of the newest foe on the bandwagon of environmental adversaries can aptly be attributed to plastics. Consumers, retailers, and brands are now demanding product manufacturers to change the way goods are packaged. Recyclability, waste reduction, and composability are turning from buzzwords to business basics. Flexible packaging, having been at the forefront of packaging modernization, is now becoming increasingly popular, with its deployment having surged across myriad industries. Some of the pivotal reasons why businesses are rapidly turning to flexible packaging are listed below:

- Flexible packages are gaining momentum primarily due to recyclability and more sustainable end-of-life options than many packaging alternatives

- They offer greater convenience for consumers by incorporating features such as spouts, zip locks, and resealable closures.

- These packages are compact and sleek, requiring fewer trucks for transportation, thereby consuming less fuel and generating less air pollution.

- Prevent product tampering and safeguard perishable/liquid goods against damage during transport.

- Creative and unique packaging appeals shoppers and boosts sales.

With a massive flurry of products, the consumer marketplace is highly saturated. This sea of products presents businesses with a huge challenge to make their product stand out from hundreds of other similar products. This is where flexible packaging comes into play. With flexible packaging one can choose virtually any design, color, size, shape, or surface finish for the package, making their product stand out on the shelves. Driven by the burgeoning craze for innovative and convenient packaging the global flexible packaging market is slated to surpass $250 billion by the year 2024.

According to the statistics consolidated by a Harris Poll commissioned by the Flexible Packaging Association, 83 percent of all brands are presently using flexible packaging of some kind. Additionally, 26 percent of brands have augmented the deployment of flexible packaging over the last 5 years, while 31 percent intend to augment their flexible packaging use in the coming years.

Multi-sensory packaging

Incorporation of multisensory elements is a growing trend in the flexible packaging space. In a fiercely competitive scenario, where various market majors are experimenting with product packages to incubate state-of-the-art, improved packaging solutions, to profitably address market needs for sustainability, a few years ago, Clondalkin Flexible Packaging launched an innovative solution for tactile packaging. Apparently, Clondalkin, the specialized producer of shrink sleeves and lidding solution, took packaging to the next level by integrating packages with pioneering tactile features such as softness and relief. This innovative technology enables brand owners to present a premium experience to shoppers when they hold the product; a critical mark in the buying process. If used sagaciously, with such packages, brand owners can convey vital product characteristics to shape consumer’s perception and emotional connection, and create a positive impact on their buying behavior. This revolutionary flexible packaging technology provides endless opportunities in the domain of multi-sensory packaging.

Sustainable development gains momentum

Sustainable development is not predicted to take a back seat anytime soon. Indeed, its influx in the automobile, aviation, energy, and manufacturing sectors has prompted packaging behemoths to slay plastics and other harmful materials used in packaging. More and more brands are now turning to bio-based and compostable flexible packaging that offers sustainable, cost-effective, and user-friendly options.

According to the European Supermarket Magazine, recently, the Spanish food firm Ebro Foods has become a part of CEFLEX, to fabricate more sustainable packaging formats. Reportedly, Ebro Foods has also pledged that 100 percent of its packaging will be reusable or recyclable by 2030, and it has established associations with other businesses in the value chain to attain this objective.

Packaging Strategies also cites a recent instance where Grass Run Farms, an alliance of family farms in the heartland of America that produces 100 percent grass-fed beef, debuted its first individually quick frozen fully natural ground beef patties in two sorts of sustainable packaging, resealable pouch and multi-use recyclable carton. As consumers’ lives are getting busier than ever before, the product offers a level of ease to customers by allowing them to seal back the pack after consuming the desired portion.

Giant leap in e-commerce space

The domain of e-commerce has not been left untouched by the rising trend of flexible packaging. In this industry, flexible packaging allows for lighter weight packaging along with specifically designed packages for the rigors of small package transport. Flexible packaging has been positioned to eradicate costs linked with manufacturing, waste, replacement parts, damage, returns, and shipping by allowing to transport more products with less. According to the Flexible Packaging Association, one truckload of flexible packaging is equal to 26x truckloads of glass containers. Hence, e-commerce retailers considerably benefit from enhanced shelf-life, amplified shelf space, reduced weight/size of package, eased logistical challenges, and increased overall revenue.

Enhances Cosmetics’ Appeal

Flexible packaging helps enhance the look of cosmetic products. Cosmetic manufacturers are increasingly adopting this practice driven by a host of benefits such as ease of decorating, money savings, space saving, and reduction in carbon emissions. Undoubtedly, flexible packaging delivers unmatched product freshness, purity, and quality making it easier for sellers to woo buyers. Also, consumer preferences are changing at a faster pace than ever, triggering a surge in versioning, personalization, customization, and convenient packaging formats.

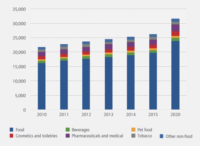

In the present backdrop, it will not be wrong to say that sustainability has become a pivotal frontier for businesses actively chasing down environmental impact. Beyond doubt, flexible packaging is the best possible solution to meet this goal in a highly profitable manner. According to the Flexible Packaging Association, the biggest market for flexible packaging is food (institutional and retail), constituting about 60 percent of shipments. Other markets are retail non-food, consumer products, pharmaceutical and medical, industrial applications, and institutional non-food.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!