Hot Products

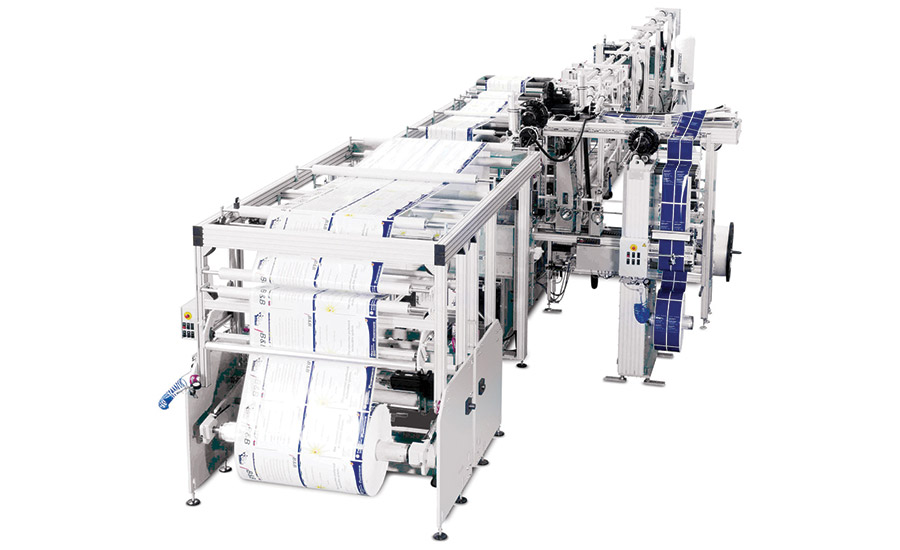

B&B Offers Side-Gusseted Bag Machine

Germany-based B&B offers the SFB 8E–T and SFB 10E–T bag machines for the production of side-gusseted bags with a flat bottom and a bag length of up to 1 m (39 inches) in height. On the SFB 10E-T machine, flexible film bag production is carried out transversal to the machine running direction with a production performance of up to 70 cycles/minute (1-up and 2-up). The SFB-8E-L also produces flat-bottom pouches, but in the traditional quad-seal way with the flat bottom panel being a separate printed web inserted inline, all at speeds up to 60 cycles/minute (1-up).

As a result of the modular machine design, customer-specific options such as perforations, handle, terminated gussets, easy open and reclosable features, patch applications, punch options and camera systems for bag quality control can be integrated any time.

Bag making machines can be equipped with an automatic format size adjustment system, minimizing changeover times and recently B&B has fully integrated its new LEAP (Line Extension Automated Packaging) cell providing a turnkey solution for automatic packaging into a Gaylord box. FP

B&B Verpackungstechnik GmbH

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!