Show Recap: Converters Expo

Recapping the 2018 Converters Expo

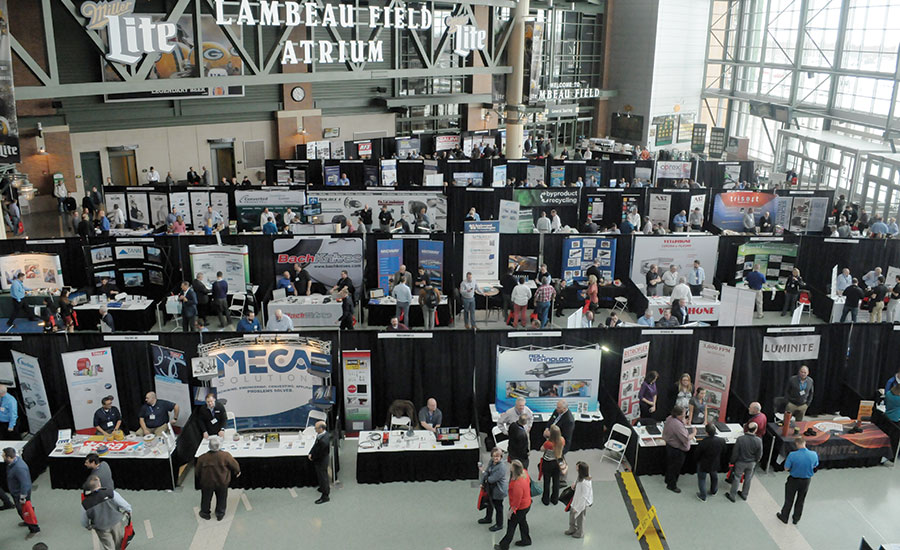

The 2018 Converters Expo held on April 18 in the heart of the “converting corridor” in the Lambeau Field atrium advanced the Expo’s reputation while exhibitors touted their own manufacturing advances.

The Expo marked its 11th year this April, and both exhibiting companies and attendance grew again. If there was any common theme seen among exhibitors, it was a message of technology and efficiency.

From the “commodity” to the “specialty” aspects of converting, equipment and other manufacturers are staying competitive with ever-new processing efficiency options. They have focused on all the ways technology can offer flexibility and improvements.

Slitting/Rewinding

In the slitting-winding side, which is often seen as the commodity end of converting, there is still a lot to examine when it comes to precision converting. Exhibitor Contract Converting allows its customers to take advantage of the Roll Express program with slitting and same day delivery. Another exhibitor, Converted Products Inc., does slitting and spooling and has grown as a niche in precision slitting and rewinding being able to handle a wider range of flexible materials than most.

Suppliers to slitting-winding converters, including exhibitors like AirTrim, American Cutting Edge, Atlas Converting, Catbridge Machinery and SRC Systems, keep converters streamlined. For example, AZTECH Converting Systems offers high-speed inspection slitter and rewinder systems.

Slitting and winding is often a step within other converting operations like flexographic printing, coating and laminating. Sierra Coating Technologies combines substrates like paper, poly and non-wovens. And it offers specialty coatings for functional properties from softness to cleansing additives.

Manufacturing Advancement

Companies like Festo Corporation express their attitude toward manufacturing advancement as diagnostics built for the future. Its services to converters include monitoring energy with compressed air analysis, systems that lead to reduced downtime and overall maximized process reliability.

Adding Value

Converters add value to every type of roll goods substrate. The array of Expo services that intersect with converting was demonstrated by companies like Adhesives Research with its emphasis on specialty adhesives, splicing tapes and release liners. Capital Adhesives formulates for packaging adhesives, labeling and more. From idler rollers by Componex to Elsner Engineering’s role in the wet wipes industry to Sonic Solutions’ ultrasonic anilox roll cleaners and Web Graphics’ supplies to flexo printers, exhibitors covered all bases.

Films

Film suppliers add to the converting scene too. Charter NEX Films, Inc. offers blown and cast films for packaging in food, consumer and protective applications. Filmquest Group is the largest merchant converter of polyester film and plays an innovative role in developing its soft-touch matte films. Another substrate supplier, Spuntech Industries, offered its “spunlace” fabrics for converters making wiping products.

Manufacturing

Converter-manufacturers have been a continuous highlight of the Expo. Long-time converters were on hand, including ASPIRO Inc., with a unique offering of sewing, sorting and contract manufacturing; Sohn Manufacturing with die-cutting and fabrication; Nichols Paper promoting its printing, laminating, waxing, sheeting and unique converting; Fredman Bag offering its flexible packaging support for food, retail and other markets; and Tesa Tape with its focus on appliance, automotive and other industries.

In all these converting aspects, there is an emphasis on keeping the U.S. competitive with its advances. Whether it’s the ingenuity of the converters or the addition of automation (by exhibitors like Rocket Industrial) or ramped-up efficiencies, the industry is busy this year, with many telling stories of growth. Additionally, the specialty nature of this industry makes it more immune to outside competition.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!